Laser die cutting is used to cut various materials that would be more difficult to cut through with the traditional steel rule die cutting. A laser beam that is usually computer controlled is programed to cut custom shapes and sizes using this method. The benefits of using a laser die would be because they are able to cut very tight and precisely, creating intricate designs, and they are high speed processes. Read More…

We know that high tech products require die cut parts that are created with precision and care. We have the highest quality standards in the die cutting industry because we know that with die cutting accuracy is so important. After we cut the prototype for your product and after receiving your approval we pledge that your orders will be shipped within ten business days or less.

CFS provides laser die cut services. Finished product can be supplied as individual pieces or on rolls. As a standalone service, the laser can create nearly perfect parts with tolerances as close as +/-0.002". Unlike traditional die cutting methods, the laser can create tricky patterns and fine details which are otherwise impossible. Offering advanced optical registration and vision inspection...

When it comes to die cutting, we are the experts! We are a Grand Rapids, Michigan based company but we offer our services to all across the United States. It is our goal to bring exceptional die cutting services to all of our clients while also providing customer service that will keep you coming back to fulfill all of your die cutting needs. Our staff has the experience you can count on to...

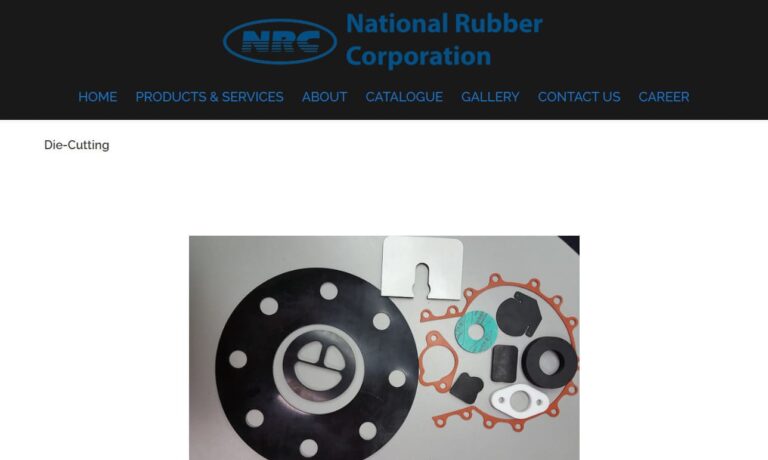

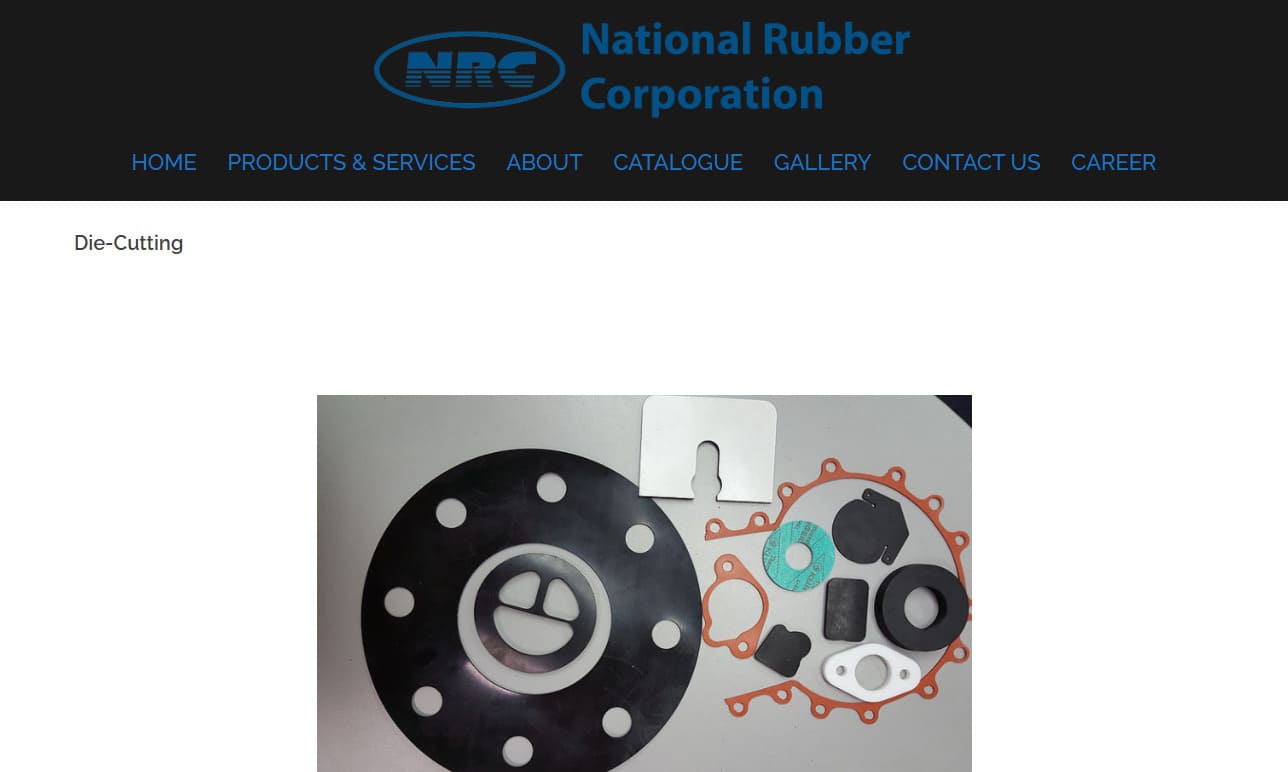

National Rubber Corporation is a nationwide leader of die cutting services for a wide variety of industries and applications. We provide die cut product quantities from prototypes and short runs to large production runs. At National Rubber, we take pride in our ability to produce accurate die cut parts that are guaranteed to meet customer specifications and perform perfectly within the intended...

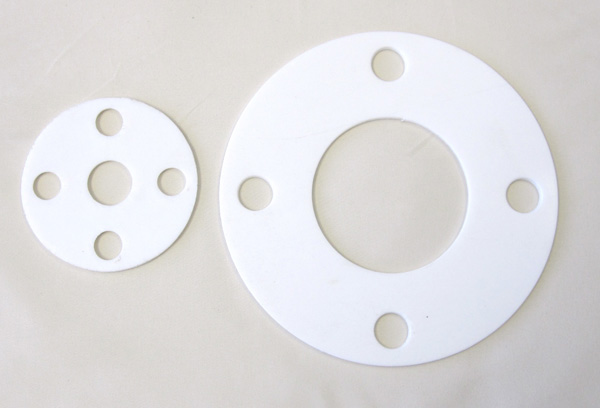

Gardico has been providing superior products and workmanship to industrial customers since 1977. Our die cutting capabilities satisfy needs for standard and custom gaskets, pads, insulators and decorative pieces in quantities from 5 or 10 to tens of thousands.

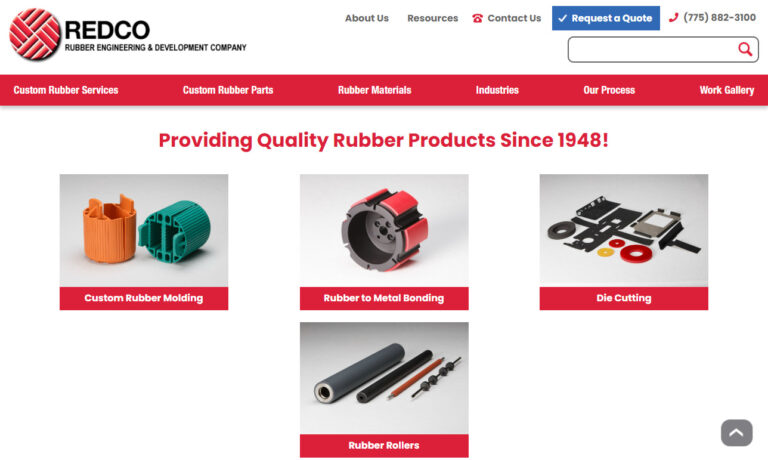

REDCO offers complete die cutting services to produce custom die cut gaskets and other custom die cuts that perfectly match our customers’ specifications. All of our steel rule dies are laser cut to guarantee quality and accuracy of the finished product. We have over 70 years of experience in die cutting non-metallic and metal parts. We strive to provide the best possible prices, the...

More Laser Die Cutting Companies

Companies that use laser die cutting may have an advantage over most since they are able to create quick turnaround times for their customers. This is a cost-effective option as well since it is computer operated and requires no die. The materials that can be used are abrasives, elastics, rubber, adhesives, marble, glass, stone, wood plexiglass, plastics, polymer films, styrene, acrylics, and fabrics. These materials are able to be die cut to produce labels, cartons, model cutting, stencils, display signage, as well as many other applications. The automotive industry, packaging, medical, electric, and construction are some of the common industries that utilize laser die cutting.

The laser for die cutting is best suitable for cutting metals because it is a harder surface to penetrate. Gasses like nitrogen or carbon dioxide are also used in addition to laser cutting to prepare cut surfaces for painting or corrosion resistance. There are several different types of lasers for die cutting- C02, Nd lasers, and Nd-YAG lasers. C02 lasers are the common, and they have the highest power continuous wave lasers. Nd lasers is still a high-speed laser but has a lower reputation while Nd- YAG laser are very high energy lasers.

Lasers are usually computer controlled through a CAD program which requires a pre-set design and is connected to a CNC machine. The CNC enables the production of large volume orders to be uniformed and efficient.

Die Cutting

Die Cutting Foam Fab

Foam Fab Gaskets

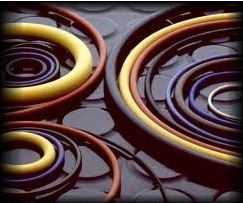

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services