Die cutters are used in the cutting process when manufacturing or producing custom materials. These tools are used to cut specialty designed shapes out of sheets or slabs of material. Materials such as metals, rubber, plastic, textiles, and wood are cut with sharp metal dies similar to a cookie cutter method or lasers. Read More…

We know that high tech products require die cut parts that are created with precision and care. We have the highest quality standards in the die cutting industry because we know that with die cutting accuracy is so important. After we cut the prototype for your product and after receiving your approval we pledge that your orders will be shipped within ten business days or less.

CFS is an ISO 9001:2015 manufacturer of custom die cuts. We supply laser, steel rule, automated flatbed and standard rotary die cutting, dieless knife cutting services. Precision die cutting achieves tolerances as tight as +/- 0.002". Services include kitting, sheeting, perforating, kiss cutting, tabs and split liners. Printing available on die cuts in performed in our ISO Class 7 Clean Room. We...

When it comes to die cutting, we are the experts! We are a Grand Rapids, Michigan based company but we offer our services to all across the United States. It is our goal to bring exceptional die cutting services to all of our clients while also providing customer service that will keep you coming back to fulfill all of your die cutting needs. Our staff has the experience you can count on to...

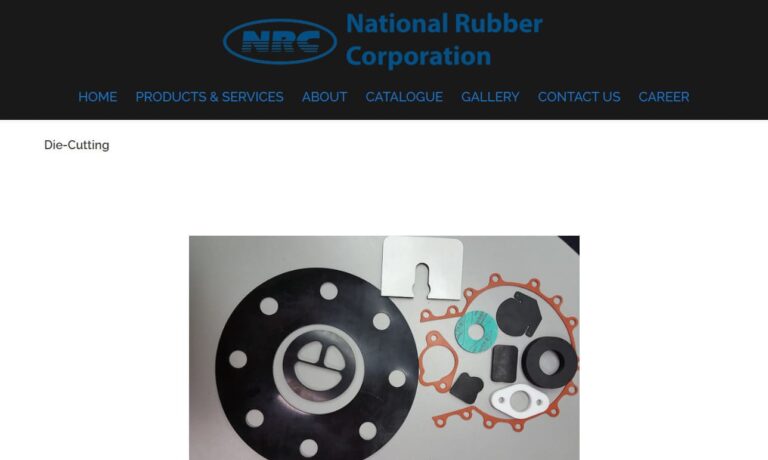

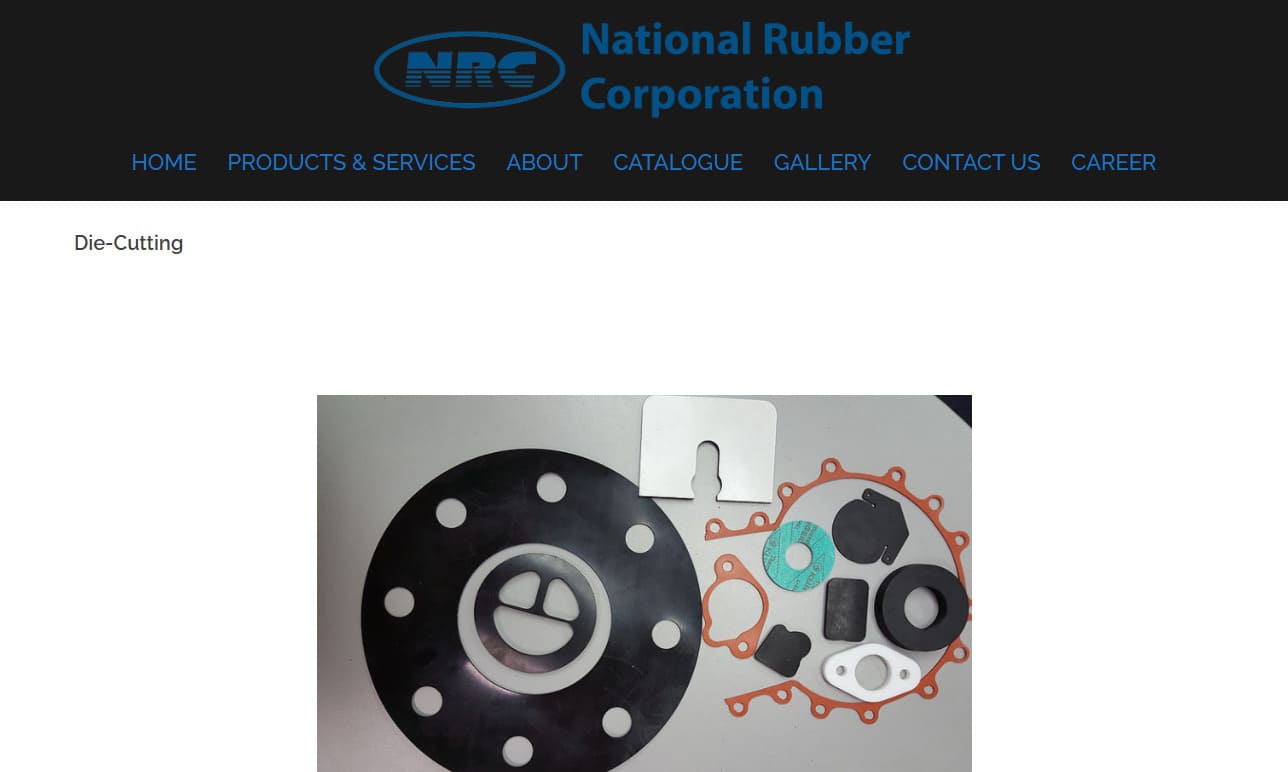

National Rubber Corporation is a nationwide leader of die cutting services for a wide variety of industries and applications. We provide die cut product quantities from prototypes and short runs to large production runs. At National Rubber, we take pride in our ability to produce accurate die cut parts that are guaranteed to meet customer specifications and perform perfectly within the intended...

Gardico has been providing superior products and workmanship to industrial customers since 1977. Our die cutting capabilities satisfy needs for standard and custom gaskets, pads, insulators and decorative pieces in quantities from 5 or 10 to tens of thousands.

REDCO offers complete die cutting services to produce custom die cut gaskets and other custom die cuts that perfectly match our customers’ specifications. All of our steel rule dies are laser cut to guarantee quality and accuracy of the finished product. We have over 70 years of experience in die cutting non-metallic and metal parts. We strive to provide the best possible prices, the...

More Die Cutter Companies

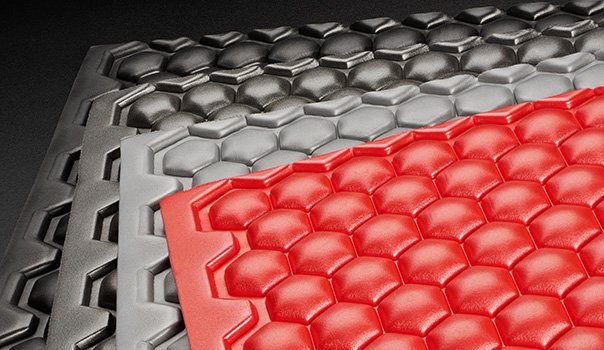

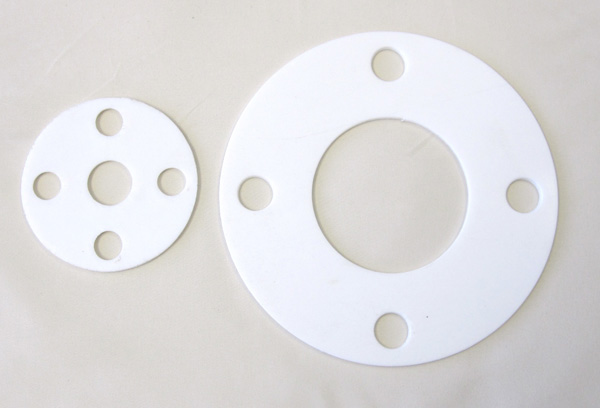

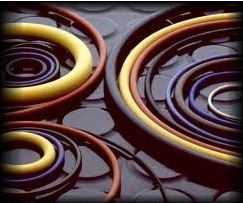

The demand for die cutting is very high since almost every industry utilizes the practice. Die cut gaskets, in particular, are very important industrial components. They are essential parts of many kinds of process equipment, and they are used in automobile engines as well to create a seal between parts in an engine block. Die cut gaskets are usually made out of rubber or metal. Everyday items such as plastic bags that are used in grocery stores and retail settings are manufactured using die cut machines. Many other items such as nameplates, shopping bags, key chains, face plates, keyboard plates, etc. are made with die cutters.

There are several different kinds of die cutters depending on what is essential for application. The simplest die cutters have thin steel blades called dies, which are used to cut specific shapes. Rotary die cutting forces a material between sharp blades on a cylindrical die and a hard-cylindrical anvil on a rotary press to cut and score materials as tight as .02. This process uses a continuous roll form and is very efficient in large volumes. Steel rule die cutting is another process that are often referred to as a cookie cutter die or clicker die. A steel rule die contains sharp blades in a particular pattern for the design and cuts through the required workable material. In ultrasonic die cutting, the vibrations of a metal horn generate heat and pressure; these vibrations are then used to die cut and seal shapes. Lastly, laser cutting involves a beam of light to create a cut and is often times controlled by a programed computer system.

Die Cutting

Die Cutting Foam Fab

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services