Die cut shapes can be made out of many materials and require a die cutter. Rubber, wood, metal, plastic, foam, and many others are all materials that are often used in the process. Die cut shapes are often thin finished products. Read More…

We know that high tech products require die cut parts that are created with precision and care. We have the highest quality standards in the die cutting industry because we know that with die cutting accuracy is so important. After we cut the prototype for your product and after receiving your approval we pledge that your orders will be shipped within ten business days or less.

CFS is an ISO 9001:2015 manufacturer of custom die cuts. We supply laser, steel rule, automated flatbed and standard rotary die cutting, dieless knife cutting services. Precision die cutting achieves tolerances as tight as +/- 0.002". Services include kitting, sheeting, perforating, kiss cutting, tabs and split liners. Printing available on die cuts in performed in our ISO Class 7 Clean Room. We...

When it comes to die cutting, we are the experts! We are a Grand Rapids, Michigan based company but we offer our services to all across the United States. It is our goal to bring exceptional die cutting services to all of our clients while also providing customer service that will keep you coming back to fulfill all of your die cutting needs. Our staff has the experience you can count on to...

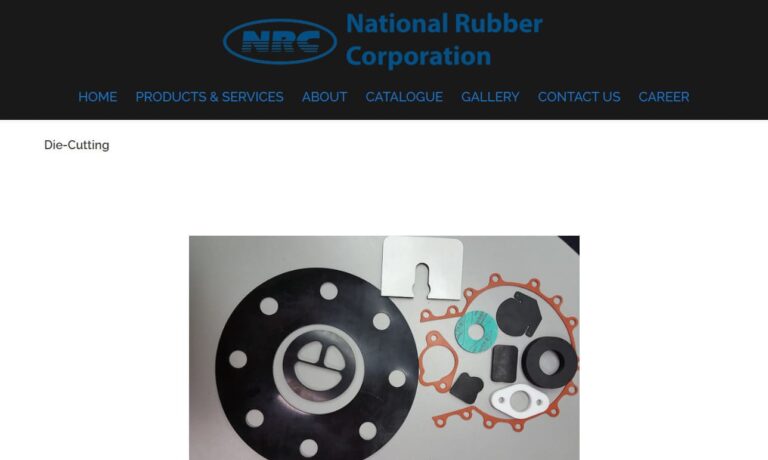

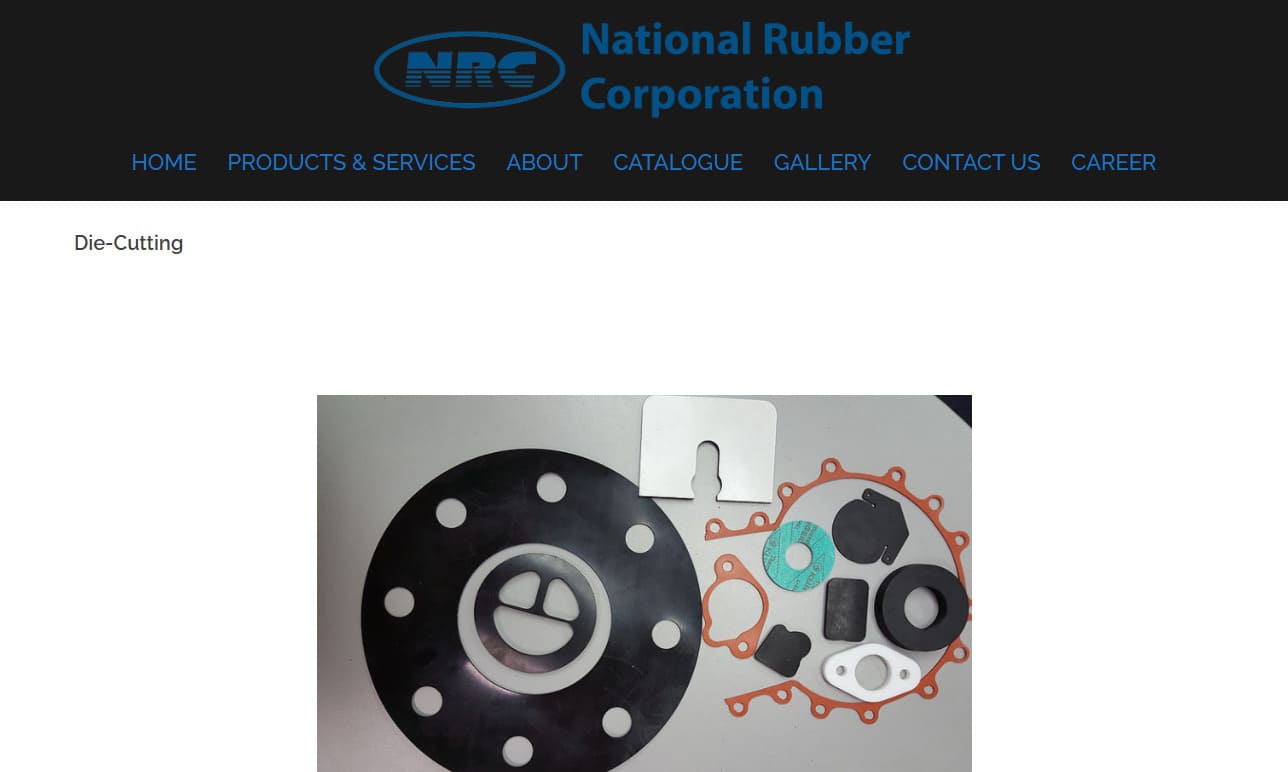

National Rubber Corporation is a nationwide leader of die cutting services for a wide variety of industries and applications. We provide die cut product quantities from prototypes and short runs to large production runs. At National Rubber, we take pride in our ability to produce accurate die cut parts that are guaranteed to meet customer specifications and perform perfectly within the intended...

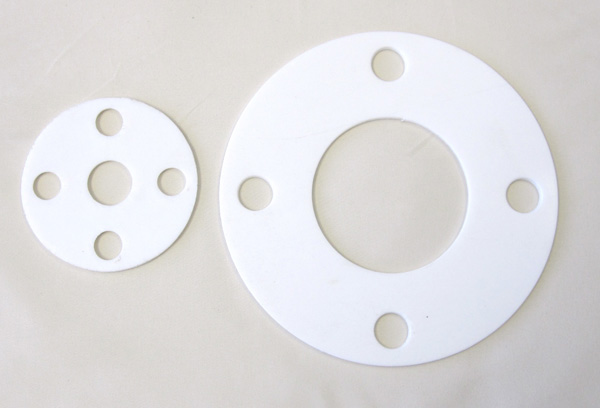

Gardico has been providing superior products and workmanship to industrial customers since 1977. Our die cutting capabilities satisfy needs for standard and custom gaskets, pads, insulators and decorative pieces in quantities from 5 or 10 to tens of thousands.

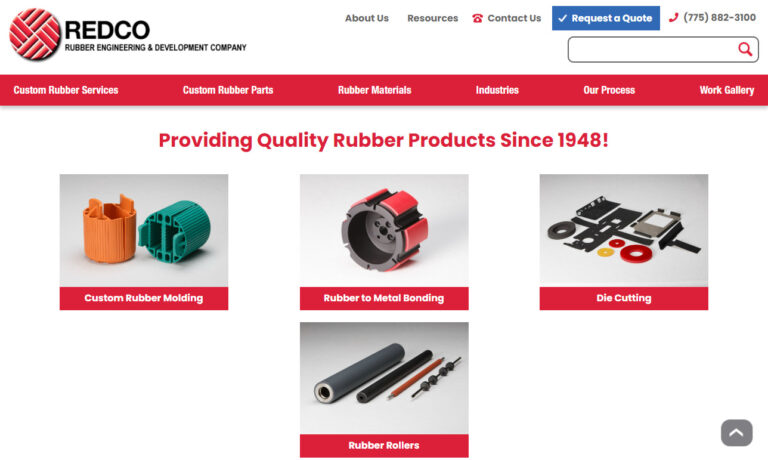

REDCO offers complete die cutting services to produce custom die cut gaskets and other custom die cuts that perfectly match our customers’ specifications. All of our steel rule dies are laser cut to guarantee quality and accuracy of the finished product. We have over 70 years of experience in die cutting non-metallic and metal parts. We strive to provide the best possible prices, the...

More Die Cut Shape Companies

Die Cut Products: Comprehensive Guide to Types, Applications, and Benefits

In today's advanced manufacturing landscape, die cut products have become indispensable across a wide array of industries. From automotive and electronics to packaging, medical, aerospace, and consumer goods, the demand for precision die cutting services and custom die cut components continues to rise. These products, produced using specialized die cutting machines and advanced fabrication processes, are essential for creating accurate, consistent, and high-quality parts at scale. Whether you’re seeking custom gaskets, foam inserts, adhesive tapes, or electrical insulation components, die cutting is the solution of choice for companies focused on quality, cost-effectiveness, and product performance.

Whether you are seeking die cut gaskets for sealing applications, custom nameplates, intricate signage, or specialized components for electronic devices, understanding the fundamentals of die cutting—including the types of die cutters, materials used, and the range of available processes—can help you make informed decisions and select the right solution for your needs. In this guide, you’ll learn about die cutting technology, its core benefits, and how to evaluate die cutting suppliers for your next project.

What is Die Cutting? Understanding the Basics

Die cutting is a versatile fabrication process that involves the use of a die—a specialized tool shaped to a specific pattern—to cut, form, or emboss materials into precise shapes. The die cutting process is used on a variety of substrates including metal, rubber, foam, plastics, paper, textiles, and composites. The choice of die cutting method depends on the material, quantity, tolerances, and complexity of the required parts. Modern die cutting leverages both manual and automated die cutting machines, including CNC-controlled systems for enhanced speed and accuracy.

- Custom Die Cutting: Tailoring the die to meet specific design and dimensional requirements for unique applications. This enables production of non-standard parts for specialized functions in electronics, automotive, medical, and industrial settings.

- Industrial Die Cutting: High-volume production of components for sectors like automotive, aerospace, medical, and electronics. Industrial die cutting ensures consistent quality, repeatability, and cost-efficiency for OEMs and contract manufacturers.

- Digital Die Cutting: Leveraging computer-controlled systems for greater flexibility and rapid prototyping. Digital die cutting is ideal for short runs, custom shapes, and quick design iterations.

Looking to learn more about the die cutting process or how to choose the best die cutting method for your project? Explore our in-depth guide below for answers to common questions and expert insights.

Types of Die Cutters: Comparing Methods and Use Cases

There are several types of die cutting machines and technologies available, each offering distinct advantages depending on the application, production volume, material type, and desired accuracy. Below we detail the most common die cutting methods used by industry-leading die cutting companies. If you're wondering, "Which type of die cutting is best for my application?" or "How do I compare rotary, flatbed, and laser die cutting?", this section will help clarify your options.

Flatbed Die Cutting

Flatbed die cutting utilizes a flat die and hydraulic or mechanical press to cut materials. This method is well-suited for thicker materials, larger parts, and lower-to-medium volume production runs. Flatbed die cutters offer flexibility in tooling and are commonly used for cutting foam, rubber, gasket materials, leather, and textiles. They are often chosen for applications requiring robust, durable parts with precise geometries.

- Ideal for short runs and prototyping, as well as for testing new designs before full-scale production.

- Handles thicker and rigid materials, making it suitable for automotive gaskets, insulation pads, and industrial seals.

- Cost-effective for lower production quantities, minimizing up-front tooling investment.

- Frequently used for converting services, such as kiss cutting, perforating, and embossing.

Rotary Die Cutting

Rotary die cutting forces a continuous material web between a cylindrical die and a hard cylindrical anvil on a rotary press. This technique can cut and score materials with high precision, reaching tolerances as tight as 0.02 inches. Rotary die cutters are optimal for high-speed, high-volume production and are widely used for pressure-sensitive adhesives, tapes, labels, flexible packaging materials, and medical device components. Their ability to produce parts at high speeds makes them a favorite for OEMs seeking scalable solutions.

- Efficient for large production volumes and continuous production lines.

- Consistent cut quality and tight tolerances, critical for precision parts in electronics and healthcare.

- Best for thin, flexible materials such as adhesive-backed foams, films, and tapes.

- Enables advanced operations like multi-layer lamination, scoring, and inline printing.

Steel Rule Die Cutting

Steel rule die cutting—sometimes referred to as cookie cutter die or clicker die cutting—employs a die made of sharp steel blades arranged in a custom pattern. The die is pressed into the material to produce the desired shape. This process is commonly used for gaskets, packaging inserts, foam pads, and rubber seals. Steel rule dies can be rapidly fabricated, making them suitable for both prototypes and medium production runs.

- Cost-effective for medium to high volumes, balancing tooling investment with part complexity.

- Versatile for a variety of materials and shapes, including foam, plastics, and textiles.

- Quick tooling changes and rapid turnaround, ideal for product development and custom orders.

- Popular for die cut packaging, promotional materials, and retail displays.

Laser Die Cutting

Laser die cutting utilizes a focused laser beam to cut, score, or engrave materials. Controlled by computer-aided design (CAD) programs, laser die cutters offer exceptional accuracy and are ideal for intricate patterns and thin substrates. This technology is often used for electronics, medical devices, labels, prototype parts, and applications where non-contact cutting is critical. Laser die cutting eliminates the need for physical tooling, reducing lead times and enabling rapid design changes.

- Highly precise, non-contact cutting—perfect for ultra-fine details and sensitive materials.

- No need for physical tooling—reducing setup costs and enabling faster time to market.

- Perfect for detailed and complex shapes, such as microfluidic devices and custom electronics components.

- Supports engraving and marking for part identification and branding.

Ultrasonic Die Cutting

Ultrasonic die cutting uses the vibrations of a metal horn to generate heat and pressure, which are applied to the material for cutting and sealing. This process is particularly effective for synthetic fabrics, films, and nonwovens, as it can create clean, sealed edges without fraying or residue. Ultrasonic cutting is favored in medical, hygiene, and textile product manufacturing where cleanliness and edge integrity are essential.

- Simultaneous cutting and edge sealing—ideal for filtration, medical disposables, and personal care products.

- Minimizes material waste and contamination, supporting cleanroom manufacturing requirements.

- Ideal for medical, hygiene, and textile products, such as face masks, wound dressings, and sterilized packaging.

- Reduces the need for secondary finishing processes.

Waterjet and EDM Die Cutting

Other advanced methods include waterjet die cutting and EDM (Electrical Discharge Machining) die cutting. Waterjet cutting uses high-pressure water (often with abrasives) to slice through metals, composites, and ceramics with minimal heat-affected zones—ideal for applications requiring pristine edges and no thermal distortion. EDM is used for ultra-hard materials and micro-miniature parts where traditional die cutting isn't feasible. These specialized processes are often selected for aerospace, defense, and high-performance industrial components.

- Non-thermal cutting for sensitive or heat-prone materials.

- Enables high-precision, intricate geometries.

- Suitable for hard-to-machine metals, ceramics, and exotic composites.

- Common for aerospace, medical implants, and advanced electronics.

Still unsure which die cutting method fits your needs? Contact our technical team for a side-by-side comparison tailored to your material, part geometry, and production goals.

Materials Used in Die Cutting: Selecting the Right Substrate

Choosing the appropriate material is critical to the success of any die cut product. The choice of substrate directly affects component durability, functionality, regulatory compliance, and cost. Die cutting can be performed on a wide range of materials including:

- Metals: Aluminum, stainless steel, copper—used for engine gaskets, EMI/RFI shielding, and electronic enclosures. Metal die cut parts offer thermal and electrical conductivity, corrosion resistance, and strength.

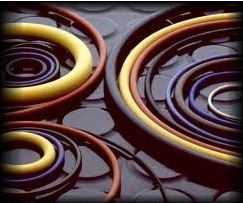

- Rubber: Nitrile, silicone, EPDM, neoprene—ideal for seals, gaskets, cushioning, and vibration dampening. Rubber die cuts are widely used for automotive, HVAC, and industrial sealing applications.

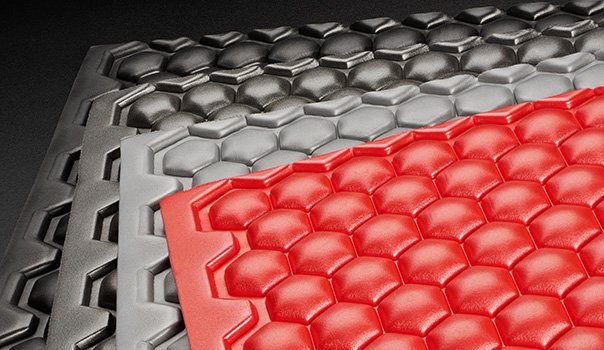

- Foam: Open cell, closed cell, polyurethane, polyethylene—used in packaging, insulation, acoustic panels, and protective pads. Foam die cut components offer impact absorption, insulation, and lightweight properties.

- Plastics: PVC, PET, polycarbonate, acrylic—common for overlays, spacers, and display components. Plastic die cutting is popular for control panels, membrane switches, and protective covers.

- Papers and Films: Pressure-sensitive adhesive (PSA) tapes, release liners, labels, decals, and graphic overlays. Paper and film die cuts are essential for product labeling, branding, and identification.

- Textiles and Nonwovens: Used in apparel, medical disposables, filtration media, hygiene products, and industrial wipes.

- Specialty Laminates and Composites: For demanding applications in aerospace, electronics, and renewable energy, where multi-layer construction enhances performance.

Not sure which material best suits your application? Contact our material experts for personalized recommendations tailored to your industry and product requirements.

Industries That Rely on Die Cut Products

The versatility and precision of die cutting make it a preferred choice for a diverse set of industries. Die cut solutions are engineered to meet the specific requirements and regulatory standards of each sector, ensuring compliance, safety, and superior performance:

- Automotive: Die cut gaskets, seals, vibration dampers, interior trim components, and thermal insulation pads. Used in engines, transmissions, dashboards, and soundproofing.

- Electronics: EMI/RFI shielding, thermal management pads, insulation, spacers, display overlays, and circuit board components. Die cut parts help protect sensitive electronics from interference, heat, and vibration.

- Medical: Disposable medical device components, wound care pads, diagnostic test strips, adhesive tapes, and biosensor substrates. Medical die cutting complies with FDA and ISO 13485 standards.

- Packaging: Custom inserts, protective foam pads, folding cartons, pressure-sensitive labels, tamper-evident seals. Die cut packaging enhances product safety, branding, and shelf appeal.

- Aerospace: Lightweight gaskets, high-performance insulation, vibration control solutions, and flame-retardant barriers. Aerospace die cut parts meet stringent FAA, NADCAP, and MIL-SPEC requirements.

- Consumer Goods: Decorative elements, decals, signage, custom promotional materials, and point-of-purchase displays.

- Renewable Energy: Die cut films and foils for battery insulation, solar cell assembly, and wind turbine components.

- Industrial Equipment: Machine gaskets, mounting pads, noise reduction foams, and protective guards.

Curious about how die cut components can enhance your products or manufacturing processes? Explore real-world case studies and application examples to discover the advantages of custom die cutting for your industry.

Key Benefits of Die Cut Products

Die cutting offers a variety of advantages that make it a preferred manufacturing method for custom components. Companies rely on die cutting to:

- Precision and Repeatability: Achieve tight tolerances and consistent part quality, even in high-volume runs—critical for automotive, electronics, and medical applications.

- Customization: Easily create bespoke shapes and sizes to meet unique design requirements. Die cutting supports rapid prototyping and short-run customizations.

- Efficiency: Rapid production speeds and minimal material waste lower overall costs. Automated die cutting enables just-in-time manufacturing and scalable output.

- Material Versatility: Supports a wide range of substrates for diverse applications, from flexible foams to rigid metals.

- Enhanced Performance: Improves product reliability, safety, and functionality. For example, die cut EMI shields prevent signal interference in electronics.

- Cost Savings: Reduces labor costs with automated processes and optimized material utilization. Lower scrap rates translate to higher profitability.

- Speed to Market: Fast tooling and setup allow for quicker transitions from concept to production, enabling companies to respond rapidly to changing market demands.

- Regulatory Compliance: Die cut parts can be manufactured to meet industry-specific standards, such as RoHS, REACH, FDA, and UL.

Looking to optimize your manufacturing process with die cut components? Request a quote from trusted die cutting suppliers to compare options and find the best fit for your needs, or use our online quote form for fast, competitive pricing.

How to Choose a Die Cutting Service or Supplier

With many die cutting companies and suppliers to choose from, selecting the right partner involves considering several important factors. Are you searching for "best die cutting companies near me" or "how to choose a die cutting supplier"? Here are key criteria to evaluate:

- Experience and Expertise: Look for suppliers with a proven track record in your industry and application type. Industry certifications and customer testimonials provide confidence in supplier capability.

- Capabilities: Assess the range of die cutting technologies, materials, and value-added services offered (such as laminating, slitting, kiss cutting, assembly, and inventory management). Can the supplier handle your project from design to final packaging?

- Quality Assurance: Ensure robust inspection processes, certifications (e.g., ISO 9001, ISO 13485, UL), and traceability. Inquire about in-process and final inspection protocols to guarantee defect-free parts.

- Lead Times and Flexibility: Evaluate the supplier’s ability to accommodate urgent orders, prototyping, and design changes. Flexible manufacturing is vital for custom, low-volume, or fast-turn projects.

- Customer Support: Choose a partner with responsive customer service, technical support, and design assistance. Direct access to engineering resources can accelerate problem-solving.

- Cost and Value: Compare pricing structures, tooling costs, and overall value delivered—including after-sales support, inventory programs, and logistics solutions.

- Geographic Proximity: Consider local versus offshore suppliers based on project timelines, shipping costs, and supply chain resilience.

- Sustainability: Review a supplier’s commitment to eco-friendly materials, waste reduction, and energy-efficient processes.

Ready to start your search for a reliable die cutting supplier? Use our Comprehensive Die Cutting Directory to connect with leading manufacturers and request competitive quotes, or ask for a free consultation to discuss your project requirements.

Frequently Asked Questions About Die Cutting

- What is the difference between rotary, flatbed, and steel rule die cutting?

Rotary die cutting is best for high-speed, high-volume runs on thin, flexible materials; flatbed is suited for thicker materials and lower volumes; steel rule offers versatility and cost-effectiveness for medium runs and custom shapes. - Which materials can be die cut?

A wide range including metals, rubber, foam, plastics, paper, films, textiles, and more. The specific method and tooling will depend on your material and application. - What are common applications for die cut products?

Gaskets, seals, labels, overlays, foam inserts, packaging, medical device components, electronic parts, signage, and display elements. - How does die cutting compare to other fabrication methods like laser cutting or waterjet cutting?

Die cutting offers superior speed, accuracy, and lower costs for high-volume, repeatable parts compared to laser cutting, waterjet cutting, or manual fabrication. It is also more cost-effective for simple and repetitive shapes. - Can die cut parts be customized?

Yes—custom die cutting allows for virtually any shape, size, or material to be produced according to your specifications. Options include color matching, adhesive backing, multi-layer laminations, and part marking. - How do I request a quote for custom die cutting services?

Submit your part drawings, material requirements, and production quantities to a supplier for a detailed and competitive quote. For step-by-step guidance, visit our request a quote page. - What tolerances can be achieved with die cutting?

Tolerances depend on the die cutting method, material, and part geometry. Rotary and laser die cutting offer the tightest tolerances (as low as ±0.002"), while flatbed and steel rule die cutting are suitable for most industrial applications (typically ±0.005" to ±0.01"). - Are die cut products suitable for cleanroom or medical environments?

Yes, many die cutting companies offer ISO Class 7/8 cleanroom manufacturing, biocompatible materials, and medical-grade adhesives for FDA and ISO 13485 compliance. - Can die cut parts be delivered on rolls, sheets, or individual pieces?

Yes—suppliers can customize packaging and presentation to fit your assembly or manufacturing process, including kiss-cut rolls, sheets, or stacked parts.

Emerging Trends and Innovations in Die Cutting

As industries demand increased precision, speed, and sustainability, the die cutting sector continues to evolve. Key innovations include:

- Digital and Laser Die Cutting: Enables faster prototyping, reduced tooling costs, and intricate designs for new product development. Perfect for startups, R&D, and rapid product iteration.

- Automated Quality Control: Vision inspection and in-line measurement systems ensure defect-free parts and traceability. Real-time data supports Six Sigma, Lean, and zero-defect initiatives.

- Eco-Friendly Materials: Use of biodegradable, recyclable, and low-VOC substrates for greener manufacturing. Growing demand for sustainable die cut packaging and eco-conscious consumer products.

- Integrated Manufacturing: Combining die cutting with printing, laminating, and assembly for end-to-end solutions. Streamlines supply chains and reduces lead times.

- Smart Manufacturing: IoT-enabled equipment and data analytics optimize production efficiency and minimize downtime. Predictive maintenance maximizes machine uptime and reduces costs.

- Micro Die Cutting: Advanced micro-fabrication techniques enable the production of ultra-small, high-precision parts for microelectronics, medical devices, and wearables.

- Personalization and Customization: Digital workflows and variable data printing support personalized die cut products for marketing, packaging, and retail promotions.

Want to stay ahead in die cutting technology? Subscribe to our newsletter for updates on the latest industry trends, case studies, and technical resources, or follow us on LinkedIn for expert insights and product launches.

Get Started: Request a Quote or Consultation

If you are evaluating die cutting services or need a reliable partner for your next project, consider the following steps. Are you searching for "how to get a die cutting quote" or "best die cutting solutions for my industry"? Follow this roadmap:

- Define your part requirements (material, dimensions, tolerances, application, and regulatory needs).

- Research suppliers with relevant industry expertise and capabilities—review case studies, certifications, and customer references.

- Request samples or prototypes to validate performance, fit, and function.

- Compare quotes and lead times for best value, considering total cost of ownership and supplier support.

- Partner with a supplier that provides technical support and ongoing quality assurance to ensure consistent performance throughout your production lifecycle.

Ready to take the next step? Request a custom die cutting quote or contact our experts for a free consultation today. For additional support, browse our online resources or download technical datasheets.

Conclusion: Unlock the Value of Precision Die Cutting

Die cut products play a vital role in modern manufacturing, offering unmatched precision, flexibility, and efficiency for a broad spectrum of industries. By understanding the different die cutting processes, material options, and supplier selection criteria, you can make informed decisions that enhance product quality, reduce costs, and accelerate time to market. Whether you’re designing custom gaskets, medical device components, or innovative packaging solutions, partnering with a skilled die cutting company ensures you achieve optimal results every time.

Have more questions, or interested in learning how die cut solutions can benefit your business? Explore our additional resources, download technical datasheets, or connect with our network of certified die cutting specialists for expert support. If you’re ready to innovate, let us be your trusted partner in precision manufacturing.

Die Cutting

Die Cutting Foam Fab

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services