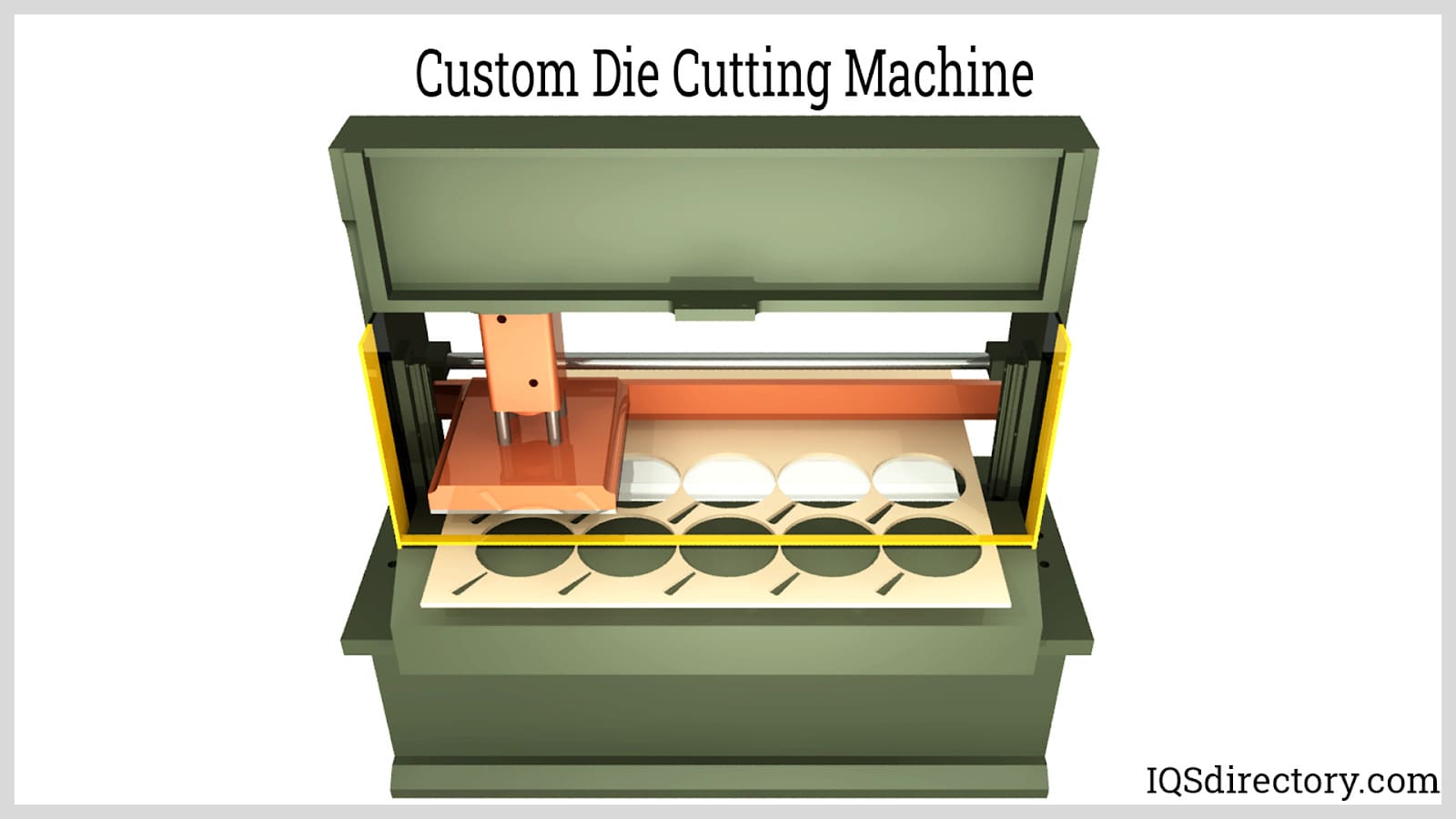

Die cut machines are used for engraving, embossing, and cutting different metal types. A die-cutting machine applies pressure to a die and pushes it through the material using a combination of rollers and cutting plates to produce a shape with clean, accurate lines. Read More…

We know that high tech products require die cut parts that are created with precision and care. We have the highest quality standards in the die cutting industry because we know that with die cutting accuracy is so important. After we cut the prototype for your product and after receiving your approval we pledge that your orders will be shipped within ten business days or less.

CFS produces industrial masking products and flexible, converted materials such as gaskets, spacers, thermal pads, and EMI shielding for finishers, OEMs, and related suppliers. Please visit customfabricate.com to request information or to browse our selection of products online.

When it comes to die cutting, we are the experts! We are a Grand Rapids, Michigan based company but we offer our services to all across the United States. It is our goal to bring exceptional die cutting services to all of our clients while also providing customer service that will keep you coming back to fulfill all of your die cutting needs. Our staff has the experience you can count on to...

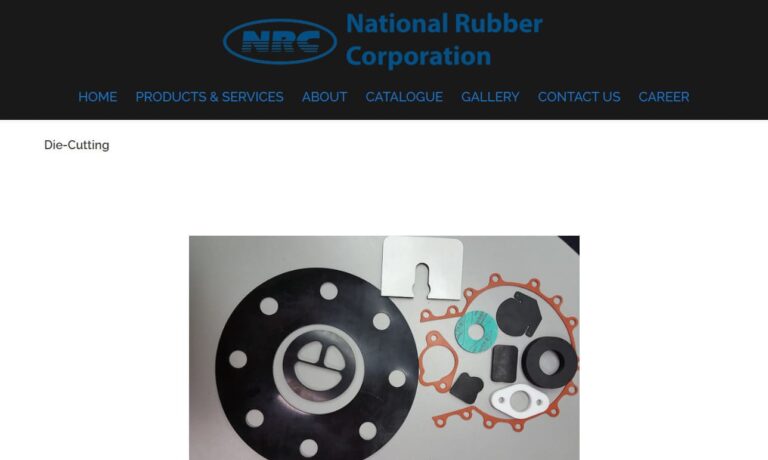

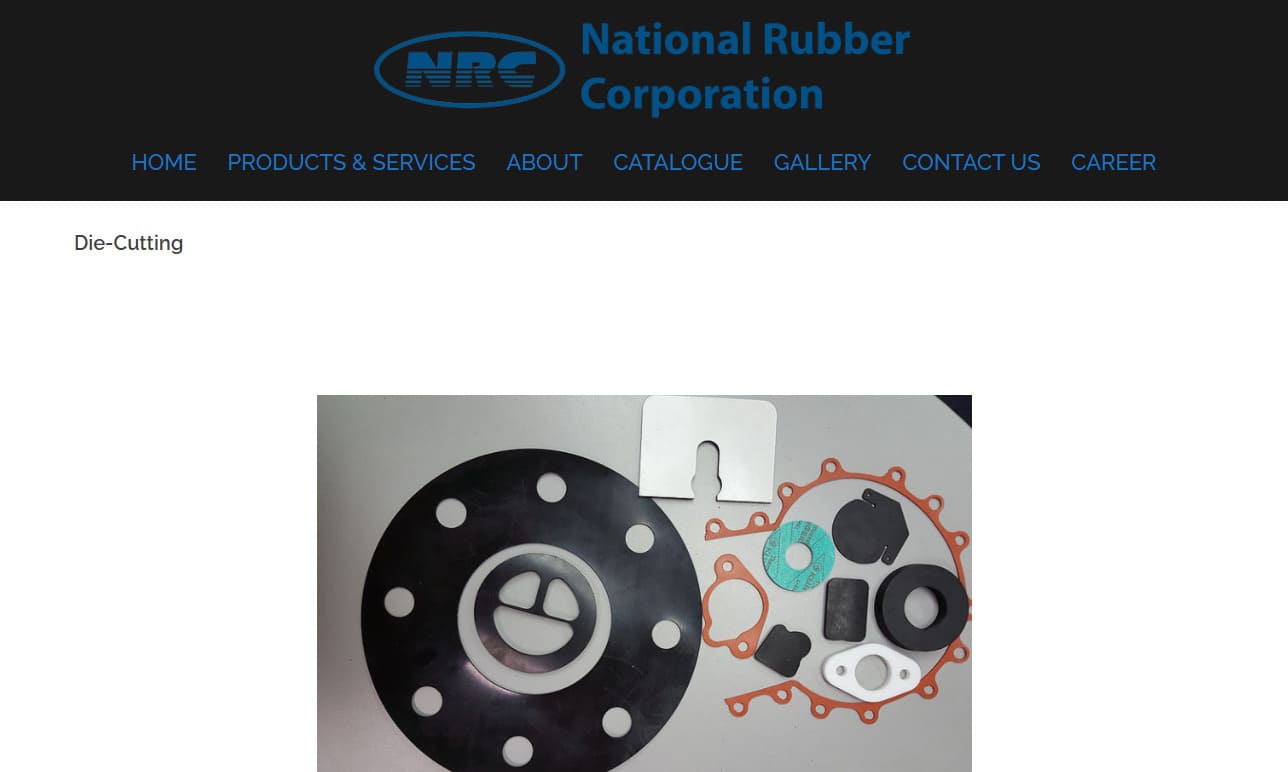

National Rubber Corporation is a nationwide leader of die cutting services for a wide variety of industries and applications. We provide die cut product quantities from prototypes and short runs to large production runs. At National Rubber, we take pride in our ability to produce accurate die cut parts that are guaranteed to meet customer specifications and perform perfectly within the intended...

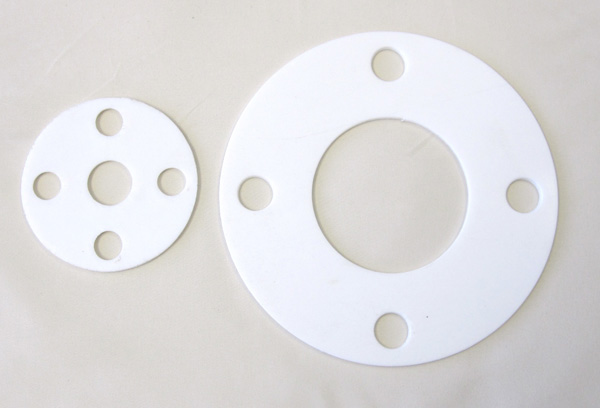

Gardico has been providing superior products and workmanship to industrial customers since 1977. Our die cutting capabilities satisfy needs for standard and custom gaskets, pads, insulators and decorative pieces in quantities from 5 or 10 to tens of thousands.

REDCO offers complete die cutting services to produce custom die cut gaskets and other custom die cuts that perfectly match our customers’ specifications. All of our steel rule dies are laser cut to guarantee quality and accuracy of the finished product. We have over 70 years of experience in die cutting non-metallic and metal parts. We strive to provide the best possible prices, the...

More Die Cut Machine Companies

Die Cutting Process

Many different die-cutting methods are utilized for slightly different purposes due to the practically unlimited range of possible die-cut product configurations and the abundance of materials from which die-cut items can be made. For instance, metal, rubber, and most other materials can be precisely cut through laser die cutting.

Additionally, laser die cutting designs can be programmed into a computer and carried out by computer-controlled machinery, making the operation incredibly quick and accurate. However, this process has a few drawbacks, including its relatively high cost and energy consumption compared to other approaches.

Steel rule dies are significantly easier to use; they require pressing a preformed metal pattern into a material. Although this method takes longer, it is cheaper and uses less energy. Blade-type rotary die cutting and ultrasonic die cutting are other methods of die cutting. Overall, die cutting is an effective, low-waste method of producing thin, custom-shaped goods if planned and carried out properly.

Considerations When Die Cutting

- Avoid abrupt corners and acute angles. When the matrix is taken off following the die-cutting process, it could tear, producing unnecessary waste.

- Create a bleed area so that the design artwork extends at least 1/16" past the label's margins. This makes it possible to prevent unintentional white spaces.

- Ensure that the shape's line is properly included. Declare the die line to be a particular spot color and to be linked lines on a separate layer.

Types of Die Cut Machines

The types of die cut machines include:

Manual Die Cut Machine

Lightweight, inexpensive manual die cutters are the most common option. The crafter must line up the die with the chosen material and turn the manual crank on the side of the die to turn it. With manual die cutters, various dies can be utilized, and many craftspeople prefer the hands-on method and the ability to see where the cutting is being done precisely.

Electric Die Cut Machines

When using an electric die cutter, simply load a die cartridge with the required design, and the machine takes care of aligning and cutting it. Although less portable than manual die cutters, electric die cut machines require less work and offer less room for error, allowing more time to complete other jobs.

Additionally, software must be installed on a computer to use electric die cutters. This may limit the selection of dies, but unique dies can be created with skill. The sandwich comprises the cutting plates, the paper to be cut, and the die that will be applied.

They are far more difficult to break through human error because an electric die-cut machine won't feed a misplaced sandwich through the rollers.

Flatbed Die Cutting

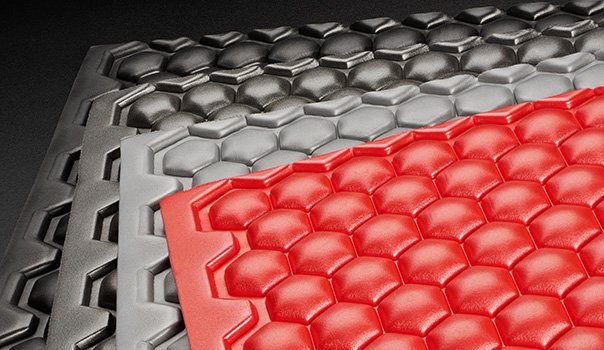

Flatbed die cutters force a die down on a sheet of material using hydraulic presses and other lifting mechanisms. In general, low-volume and larger-sized products use flatbed die cutting. Compared to most label stocks, flatbed die presses are typically better suited for heavier materials over 1/8" thick, including felt, fiber, textiles, and metals.

Uses of Die Cut Machines

There is no restriction on the demand for die-cut items. Die-cut gaskets are crucial for the safe and efficient operation of a wide range of equipment in industrial settings.

Metal, rubber, plastic, foam, and even soft materials like felt can be used to create die-cut industrial items. Access to decorative nameplates, logos, and comparable products is frequently necessary for commercial operations like offices.

These products, as well as individual letters for signage, panels for electronics, and a variety of other commercial goods can be produced at low cost and in large quantities using die cutting. To meet the varied demand for die-cut items, different die-cut processes are set up differently. For example, while a large-scale business is more likely to supply stock products in large quantities, a smaller die-cutting operation might offer custom die-cut products to the customer's specifications.

Choosing the Right Die Cut Machine Manufacturer

For the most beneficial outcome when purchasing a die cut machine from a die cut machine manufacturer, it is important to compare several manufacturers using our directory of die cut machine companies. Each die cut machine manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each die cut machine company website using our patented website previewer for an understanding of what each business specializes in. Then, use our simple RFQ form to contact multiple die cut machine businesses with the same form.

Die Cutting

Die Cutting Foam Fab

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services