Shapes made out of foam sheets by a die cutter are known as die-cut foam items. Die cutters are stamping or rolling devices that cut flat sheets into custom-designed forms. Metal, plastic, wood, rubber, and other materials can all be cut into desired forms using die cutters. Several different things are made with die cut foam. Read More…

We know that high tech products require die cut parts that are created with precision and care. We have the highest quality standards in the die cutting industry because we know that with die cutting accuracy is so important. After we cut the prototype for your product and after receiving your approval we pledge that your orders will be shipped within ten business days or less.

CFS is an ISO 9001:2015 manufacturer of custom die cuts. We supply laser, steel rule, automated flatbed and standard rotary die cutting, dieless knife cutting services. Precision die cutting achieves tolerances as tight as +/- 0.002". Services include kitting, sheeting, perforating, kiss cutting, tabs and split liners. Printing available on die cuts in performed in our ISO Class 7 Clean Room. We...

When it comes to die cutting, we are the experts! We are a Grand Rapids, Michigan based company but we offer our services to all across the United States. It is our goal to bring exceptional die cutting services to all of our clients while also providing customer service that will keep you coming back to fulfill all of your die cutting needs. Our staff has the experience you can count on to...

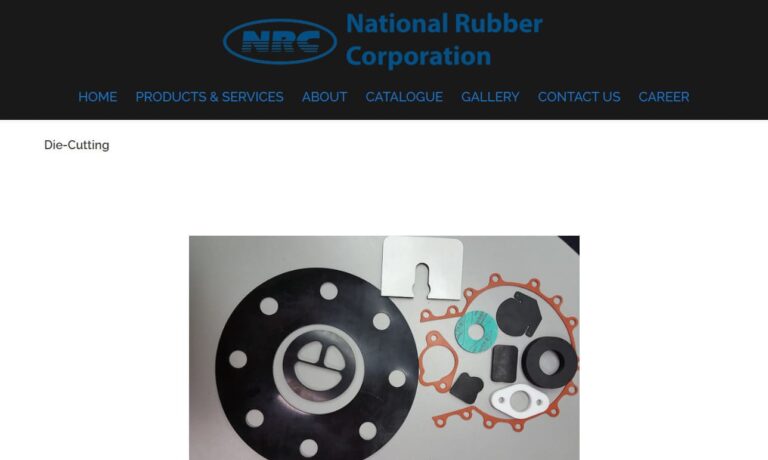

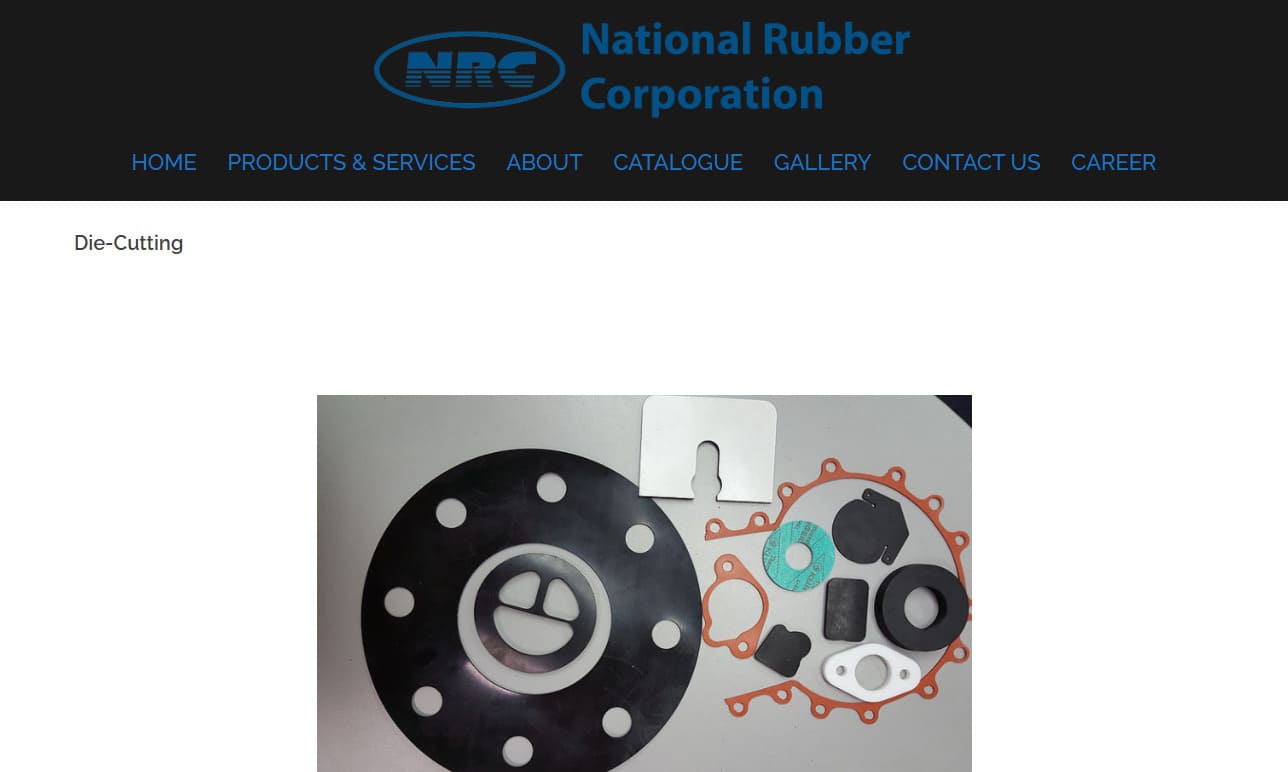

National Rubber Corporation is a nationwide leader of die cutting services for a wide variety of industries and applications. We provide die cut product quantities from prototypes and short runs to large production runs. At National Rubber, we take pride in our ability to produce accurate die cut parts that are guaranteed to meet customer specifications and perform perfectly within the intended...

Gardico has been providing superior products and workmanship to industrial customers since 1977. Our die cutting capabilities satisfy needs for standard and custom gaskets, pads, insulators and decorative pieces in quantities from 5 or 10 to tens of thousands.

REDCO offers complete die cutting services to produce custom die cut gaskets and other custom die cuts that perfectly match our customers’ specifications. All of our steel rule dies are laser cut to guarantee quality and accuracy of the finished product. We have over 70 years of experience in die cutting non-metallic and metal parts. We strive to provide the best possible prices, the...

More Die Cut Foam Companies

Comprehensive Guide to Die Cut Foam Solutions

Are you searching for the most efficient way to customize foam parts for packaging, insulation, or industrial applications? Die cut foam offers a versatile, cost-effective solution that is trusted across numerous industries. This in-depth resource explores the die cut foam process, the diverse methods available, key advantages, common applications, and tips for selecting the best die cut foam manufacturer for your project. Whether you’re a procurement specialist, engineer, or business owner, discover everything you need to know about die cut foam fabrication and services.

Foam Die Cutting Process: How Custom Foam Parts Are Made

Die cutting is a specialized fabrication technique used to produce precise, repeatable shapes from various foam materials. The process utilizes die cut machines, which are set up for specific forms and dimensions according to your application requirements. Thin blades, known as dies, are fashioned into custom profiles that cleanly cut through foam sheets and blocks.

Wondering which materials can be processed using die cutting? The answer is nearly all foam types, including open-cell and closed-cell foams such as polyethylene (PE), polyurethane (PU), ethylene-vinyl acetate (EVA), neoprene, cross-linked polyethylene (XLPE), and more. Die cutting is also used for other substrates like plastic, paper, felt, rubber, and thin metal foils, making it a universal fabrication method across multiple sectors.

Before die cutting begins, a steel die mold is engineered based on digital CAD drawings or customer blueprints. This die is installed in the die cutting machine, which then rapidly produces foam parts to the exact specifications. The process is ideal for both short-run and high-volume manufacturing, and is valued for its precision, speed, and cost control.

What Are the Steps in Custom Die Cut Foam Manufacturing?

If you’re evaluating die cut foam suppliers or planning a project, understanding the typical workflow is crucial. Here’s a step-by-step breakdown of the process:

- Material Selection: Choose the right foam type (PE, PU, EVA, XLPE, Neoprene, etc.) based on application requirements such as density, durability, chemical resistance, or cushioning properties.

- Design & Engineering: Provide detailed CAD files or drawings. Many die cut foam companies offer in-house design support to optimize your part for manufacturability.

- Tooling: Custom dies are manufactured to match your part’s shape, tolerances, and features. Tooling costs are typically low for die cutting compared to other fabrication methods like injection molding or CNC routing.

- Cutting: Foam sheets or rolls are loaded onto the die cutting machine. The machine uses the die to punch, slice, or stamp the foam material into the required dimensions.

- Secondary Operations: Depending on your needs, services like adhesive backing application, lamination, multi-layer assembly, or printing can be performed.

- Inspection & Packaging: Finished die cut foam parts are checked for quality, consistency, and dimensional accuracy. Products are then packaged for delivery.

Curious about how to optimize your die cut foam design for cost savings or performance? Ask our experts for design-for-manufacturing (DFM) tips and best practices.

Common Foam Die Cutting Methods

Choosing the right die cutting method depends on your foam material, thickness, production volume, and tolerance requirements. Explore the main types of foam die cutting below:

Steel Rule Die Cutting

Steel rule die cutting is a widely used technique for processing foam sheets and rolls. The setup involves three essential components:

- Flat die boards – Provide a rigid, stable surface for the die.

- Metal cutting blades – Precisely formed to the desired shape.

- Rubber ejection layers – Help remove finished parts from the die after cutting.

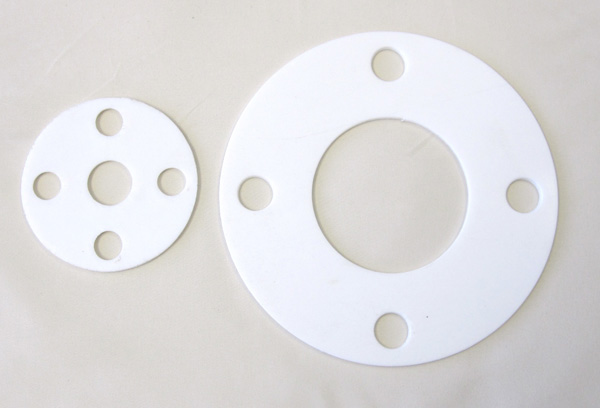

This method is ideal for thicker foam materials, custom gaskets, and small to medium-sized production runs. Steel rule dies are cost-effective to manufacture, making them suitable for prototyping and limited editions as well as ongoing production. Many buyers searching for custom die cut foam shapes or intricate foam packaging inserts prefer this approach due to its versatility and precision.

Steel rule die cutting can handle a variety of foam thicknesses and densities, making it an excellent choice for industries requiring robust protective packaging, custom inserts, or specialized sealing solutions.

Kiss Cutting

Curious about how to create foam parts with adhesive backings or easy-peel liners? Kiss cutting is the answer. Kiss cutting is a precision process where the die blade slices through the foam layer without cutting through the underlying liner or backing. This results in finished foam components that remain attached to a removable paper or film liner for simplified handling and installation.

Kiss cutting is often used for:

- Custom foam pads and self-adhesive gaskets

- Industrial insulation layers

- Protective tapes, seals, and cushioning elements

This shadow cut process is especially effective for thin foam sheets and pressure-sensitive applications where ease of application is critical. If you need foam parts that are easy to apply in the field or on an assembly line, ask your supplier about kiss cutting capabilities.

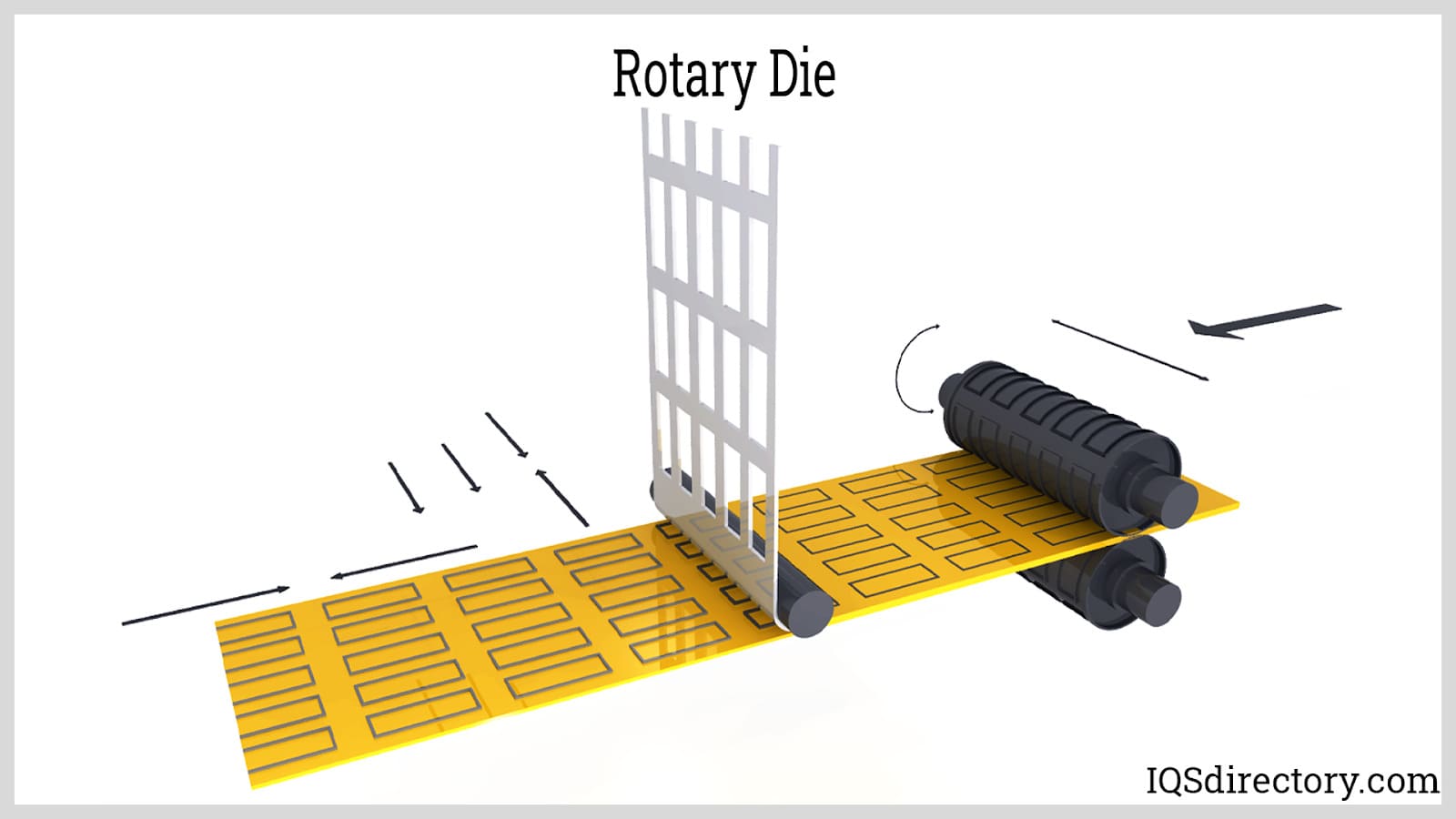

Rotary Die Cutting

If your project requires high-volume production of die cut foam parts with tight tolerances, consider rotary die cutting. This high-speed method feeds flat foam material through a cylindrical rotary die equipped with sharp cutting blades. The die rotates in sync with the moving material, cutting shapes with exceptional speed and consistency.

Rotary die cutting is ideal for:

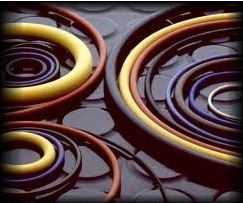

- Large production runs of foam gaskets, seals, and washers

- Thin, flexible foams such as PVC, EPDM, cross-linked polyethylene, and medical-grade foams

- Applications requiring precise, repeatable cuts at rapid speeds

Many industries—ranging from automotive to electronics and medical device manufacturing—rely on rotary die cutting for producing lightweight, functional foam components at scale. This method is particularly advantageous for continuous feed production environments, maximizing throughput while maintaining tight tolerances.

Manual Die Cutting

Looking for a hands-on, cost-effective approach for low-volume or prototyping needs? Manual die cutting uses a simple press mechanism where the die is sandwiched between plates and pressure is applied by hand, often using a crank or lever. This technique is reminiscent of a mangle and is best suited for small projects, samples, or craft applications where speed is less critical but flexibility is needed.

Manual die cutting is an excellent way to create prototypes, test new foam designs, or produce small batches of custom foam components before scaling up to automated production.

Other Cutting Technologies for Foam Fabrication

In addition to traditional die cutting, some advanced manufacturers offer laser cutting, waterjet cutting, and CNC foam cutting for projects requiring complex geometries, intricate details, or extremely tight tolerances. These digital cutting methods can be ideal for rapid prototyping, low-volume runs, or specialized industrial foam parts where traditional dies may not be practical.

Want to compare foam fabrication technologies for your application? Consult our experts for tailored recommendations.

Advantages of Die Cut Foam: Why Choose This Fabrication Method?

Die cut foam delivers a host of benefits, making it a top choice for manufacturers, designers, and engineers seeking precision, cost savings, and material flexibility. Wondering if die cut foam is right for your application? Consider these compelling advantages:

- Exceptional Design Freedom: Produce a limitless range of custom foam shapes, sizes, and profiles to match any unique requirement. Complex contours and intricate cutouts are achievable with precise die engineering.

- Material Compatibility: Works with all major foam types, including EVA foam, PE foam, PU foam, neoprene, cross-linked polyethylene (XLPE), foam rubber, and more. This flexibility ensures you can match the foam’s properties to your end-use needs.

- Low Tooling and Production Costs: Die fabrication is affordable, and the process supports economical manufacturing for both prototypes and large-scale orders. Compared to CNC machining or injection molding, die cutting often results in lower upfront investment.

- Scalable for Any Volume: Efficiently handles everything from one-off samples to millions of units with minimal changeover time. Whether you need rapid prototyping or bulk production, die cut foam adapts to your scale.

- Equipment Flexibility: Choose from clicker presses for smaller, high-precision jobs, hydraulic presses for larger surface areas, or rotary die cutters for continuous production. This range allows manufacturers to optimize their process for throughput and part complexity.

- Consistent Quality: Delivers reliable, repeatable results with tight tolerances and clean edges. Automated die cutting reduces the risk of human error and ensures uniformity between parts.

- Minimal Material Waste: Optimized die layouts maximize yield and help control raw material costs. Efficient nesting strategies reduce scrap and improve sustainability.

- Fast Turnaround: Quick setup and rapid cutting cycles enable short lead times for urgent projects. Many die cut foam companies offer expedited services for time-sensitive orders.

Want to learn how die cut foam can reduce your project costs or improve product performance? Request a cost analysis from a leading supplier.

Typical Applications of Die Cut Foam: Where Is Die Cut Foam Used?

Die cut foam is engineered to meet the needs of a wide variety of industries and end-uses. Are you exploring how die cut foam can solve your packaging, insulation, or product protection challenges? Review these popular applications to find the right fit for your business:

- Protective Packaging and Inserts: Cushion electronics, tools, medical devices, automotive parts, and fragile items during shipping and storage. Die cut foam absorbs shocks, dampens vibration, and prevents scratches or impact damage. Both custom foam packaging and off-the-shelf foam inserts leverage die cutting for a perfect fit.

- Custom Gaskets and Seals: Create airtight, watertight, or dustproof barriers for automotive, HVAC, aerospace, and industrial equipment. Visit our page on die cut gaskets for more information. Foam gaskets are often preferred for their flexibility, resilience, and sealing performance in demanding environments.

- Acoustic Insulation: Reduce noise and improve sound quality in recording studios, sound booths, offices, and manufacturing plants. Die cut foam panels and tiles are available in various thicknesses and densities to optimize acoustic performance. Ask about acoustical foam for specialized sound absorption solutions.

- Thermal Insulation: Insulate HVAC systems, appliances, and electronic enclosures with foam materials that resist heat transfer and condensation. Closed-cell foams are particularly effective for preventing energy loss and moisture ingress.

- Medical and Healthcare Products: Manufacture foam dressings, orthopedic supports, medical device pads, and patient positioning aids with biocompatible, hypoallergenic foams. Medical-grade die cut foam ensures patient safety and comfort while maintaining regulatory compliance.

- Automotive Components: Produce vibration mounts, dashboard insulators, weatherstripping, and custom interior padding for vehicles of all types. Die cut foam parts help manufacturers meet stringent requirements for comfort, safety, and durability in automotive interiors and systems.

- Retail and Promotional Items: Craft novelty foam products, branded giveaways, display inserts, and custom signage for marketing and events. With die cut foam, businesses can create eye-catching, memorable promotional items at scale.

- Sports and Fitness Equipment: Fabricate protective pads, grips, and exercise mats for athletics, yoga, and rehabilitation. Die cut foam is a staple in sports equipment manufacturing due to its shock-absorbing and comfort properties.

- Consumer Electronics: Use die cut foam inserts to secure and protect laptops, cameras, drones, and audio devices within carrying cases and retail packaging. Anti-static and conductive foam options are available for sensitive electronics.

Have a unique application in mind? Die cut foam can be tailored to almost any use case—contact a specialized die cut foam company to discuss your project’s requirements and get expert guidance. Connect with a foam expert to explore custom applications.

Types of Foam Materials for Die Cutting

Choosing the appropriate foam material is critical for optimizing performance, durability, and cost in your specific application. Here’s an overview of the most commonly die cut foam materials:

- Polyethylene (PE) Foam: Durable, flexible, and resistant to moisture—ideal for packaging, case inserts, and insulation. PE foam is known for its closed-cell structure, providing excellent shock absorption and buoyancy.

- Polyurethane (PU) Foam: Lightweight, soft, and available in a wide range of densities—commonly used for cushioning, sound absorption, and medical pads. Open-cell PU foam is especially effective for acoustic and comfort applications.

- EVA (Ethylene-Vinyl Acetate) Foam: Excellent shock absorption, flexibility, and weather resistance—perfect for sports equipment, footwear, and specialty packaging. EVA foam is also popular for craft and display applications due to its vibrant color options.

- Neoprene Foam: Offers chemical and water resistance, plus good thermal insulation—used for gaskets, wetsuits, and protective gear. Neoprene’s closed-cell structure makes it ideal for marine and automotive sealing applications.

- Cross-Linked Polyethylene (XLPE) Foam: Closed-cell, strong, and resistant to chemicals and UV exposure—suitable for automotive, medical, and marine industries. XLPE foam is valued for its fine cell structure and smooth finish, making it great for aesthetic applications as well.

- Conductive and Anti-Static Foams: Used to protect electronic components from static discharge during handling and shipping. These specialty foams are engineered for ESD (electrostatic discharge) protection in electronics manufacturing and packaging.

- Flame Retardant and High-Temperature Foams: For applications requiring fire safety or resistance to extreme heat, such as aerospace or industrial equipment, ask about UL-rated or specialty engineered foam options.

Not sure which foam type is right for your needs? Ask a die cut foam expert to recommend the best material for your application based on environmental exposure, mechanical stress, and regulatory requirements. Get a material consultation today.

How to Choose the Right Die Cut Foam Company

Ready to source die cut foam parts for your next project? Selecting the right die cut foam company can make all the difference in quality, lead time, and cost-effectiveness. Here are actionable steps and questions to guide your decision:

- Evaluate Capabilities: Does the company offer a full range of die cutting methods (steel rule, rotary, kiss, laser, waterjet)? Can they process your chosen foam materials and meet your dimensional tolerances?

- Review Industry Experience: Look for suppliers with a proven track record in your sector—whether it’s packaging, automotive, medical, electronics, or industrial products. Industry-specific expertise can improve your project’s success.

- Inspect Quality Systems: Do they maintain certifications like ISO 9001 or IATF 16949? Are there documented inspection and quality assurance processes? Quality control is essential for critical applications.

- Request Custom Samples and Prototypes: A reputable die cut foam manufacturer should provide samples to verify fit, finish, and performance before committing to full production. Prototype runs help identify potential design improvements.

- Check Lead Times and Flexibility: Can the supplier meet your delivery schedule? Are they equipped to handle both small and large orders? Flexibility matters if your needs change or if you face supply chain disruptions.

- Assess Value-Added Services: Do they offer engineering support, adhesive lamination, assembly, printing, or fulfillment options? Integrated services can streamline your supply chain and reduce overall costs.

- Compare Pricing and Terms: Obtain detailed quotes from multiple vendors to ensure competitive pricing, transparent costs, and clear payment/shipping policies. Don’t forget to ask about minimum order quantities and volume discounts.

- Read Customer Reviews and Testimonials: What do previous clients say about reliability, communication, and product quality? Check for case studies or references in your industry.

Our comprehensive directory of die cut foam companies makes it easy to compare suppliers. Each listing features a detailed profile, highlights core capabilities, and provides a direct contact form for inquiries or quote requests. Utilize our patented website previewer to quickly assess each company’s strengths, and use our streamlined RFQ tool to send inquiry forms to multiple suppliers at once—saving you valuable time during the sourcing process.

Not sure where to start? Browse our directory or get matched with top-rated suppliers based on your industry and project needs.

Frequently Asked Questions About Die Cut Foam

- How do I specify my requirements for custom die cut foam?

Provide your supplier with detailed drawings, dimensions, material preferences, tolerance requirements, and annual volume estimates. Clear communication ensures you receive parts that meet your exact needs. Curious about the quoting process? Request a quote now. - What is the typical lead time for die cut foam parts?

Lead times vary depending on complexity, order size, and supplier capacity. Many projects can be completed within 1–2 weeks after finalizing the design and material selection. Need a rush order? Ask about expedited services. - Can die cut foam be laminated or printed?

Yes. Many die cut foam suppliers offer secondary services such as adhesive lamination, multi-layer assembly, screen or digital printing, and custom packaging solutions. Looking for turnkey solutions? Explore lamination and assembly. - Are there minimum order quantities for die cut foam?

Minimums vary by manufacturer and project type. Some suppliers offer no-minimum or low-minimum production runs, especially for prototyping or specialty foam parts. Always ask about MOQs during the quoting process. - What tolerances are achievable with die cut foam?

Typical tolerances depend on foam type, thickness, and cutting method. Many suppliers can achieve tolerances as tight as ±0.010” (0.25mm) for precision applications. Discuss your tolerance requirements with your supplier during the design phase.

Ready to Start Your Die Cut Foam Project?

Are you prepared to take the next step in sourcing high-quality, custom die cut foam components? Explore our nationwide directory of die cutting companies to find experienced suppliers ready to assist with your project. Whether you need rapid prototyping, large-scale production, or expert material recommendations, our network connects you with industry leaders who can deliver on your requirements.

Have a specific question about die cut foam fabrication, materials, or applications? Contact us today or request a quote from multiple suppliers using our quick RFQ form. Empower your business with the precision, protection, and performance that only die cut foam can provide. Let us help you bring your custom foam project to life—reach out to our team for a free, no-obligation consultation and start optimizing your products with expertly fabricated foam solutions.

Die Cutting

Die Cutting Foam Fab

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services