A cylindrical die is used in rotary die cutting, a specialized form of die cutting, to create shapes from materials. It revolves continuously and features blades that carve off the required shape all the way around the cylinder. Because it rotates while cutting out numerous identical forms, this is highly effective. Read More…

We know that high tech products require die cut parts that are created with precision and care. We have the highest quality standards in the die cutting industry because we know that with die cutting accuracy is so important. After we cut the prototype for your product and after receiving your approval we pledge that your orders will be shipped within ten business days or less.

Rotary die cutting is the process of choice for producing thin film and pressure sensitive adhesive tape die cuts in high volume. CFS utilizes the flexibility provided by our machinery and tooling to produce in-line laminating, kiss cutting, scoring, split lining, sheeting, kitting, and perforating. Quantities from prototypes and short runs to large production volumes. Large library of materials...

When it comes to die cutting, we are the experts! We are a Grand Rapids, Michigan based company but we offer our services to all across the United States. It is our goal to bring exceptional die cutting services to all of our clients while also providing customer service that will keep you coming back to fulfill all of your die cutting needs. Our staff has the experience you can count on to...

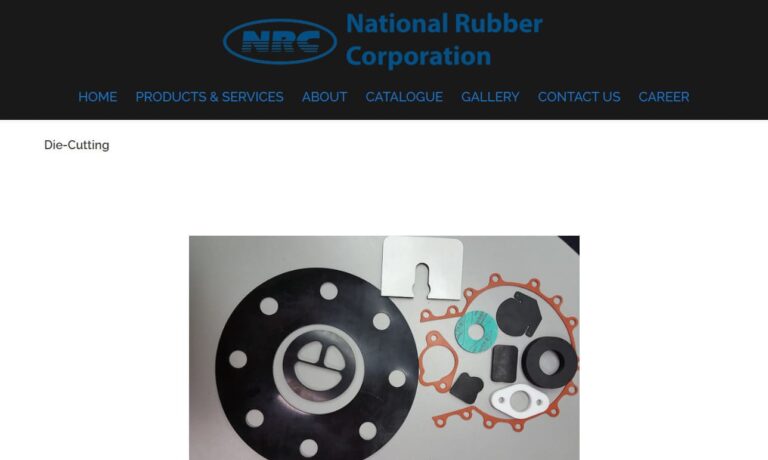

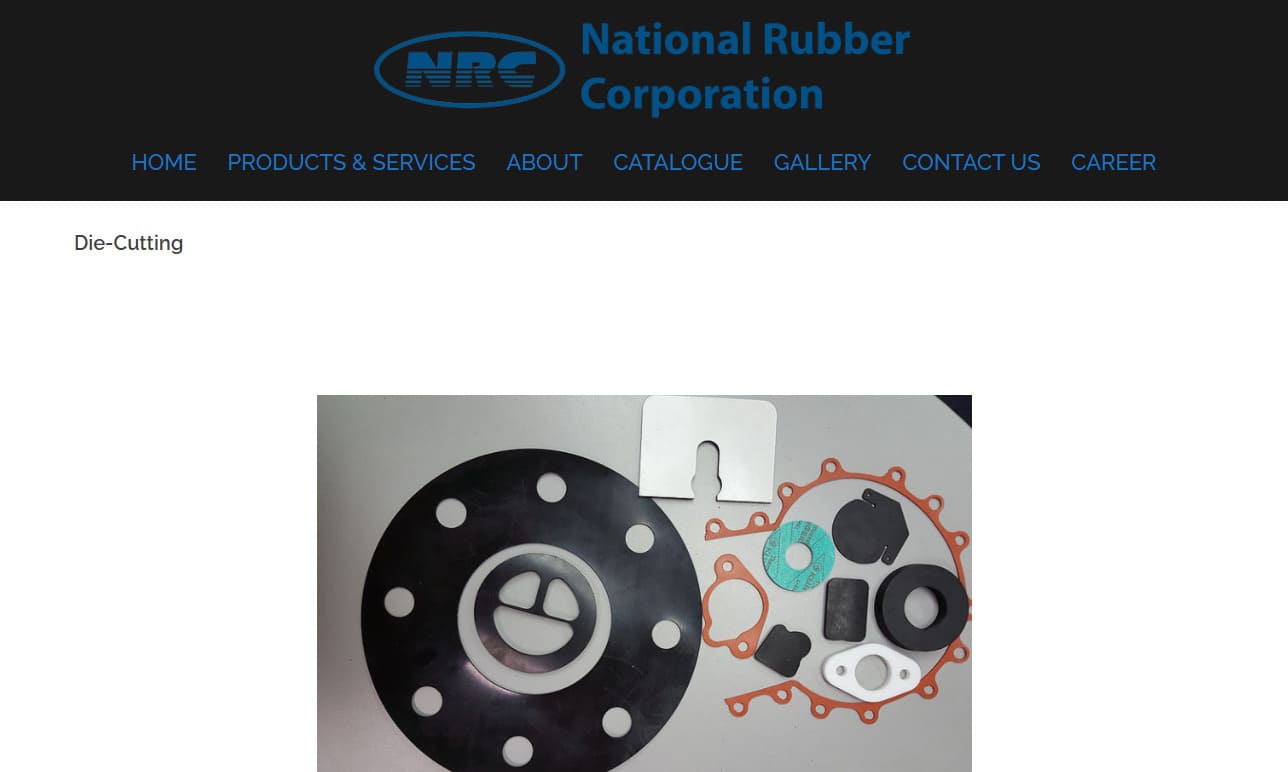

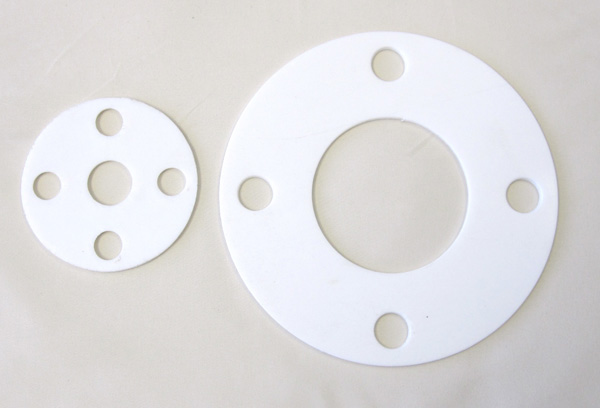

National Rubber Corporation is a nationwide leader of die cutting services for a wide variety of industries and applications. We provide die cut product quantities from prototypes and short runs to large production runs. At National Rubber, we take pride in our ability to produce accurate die cut parts that are guaranteed to meet customer specifications and perform perfectly within the intended...

Gardico has been providing superior products and workmanship to industrial customers since 1977. Our die cutting capabilities satisfy needs for standard and custom gaskets, pads, insulators and decorative pieces in quantities from 5 or 10 to tens of thousands.

REDCO offers complete die cutting services to produce custom die cut gaskets and other custom die cuts that perfectly match our customers’ specifications. All of our steel rule dies are laser cut to guarantee quality and accuracy of the finished product. We have over 70 years of experience in die cutting non-metallic and metal parts. We strive to provide the best possible prices, the...

More Rotary Die Cutting Companies

What is Rotary Die Cutting?

Rotary die cutting is a high-speed, precision fabrication process that utilizes a cylindrical die mounted on a rotary press to convert large sheets or rolls of material into specific shapes, sizes, or intricate patterns. This automated die cutting process is ideal for mass production of parts that require consistent accuracy and is widely used in a diverse range of industries, including plastic die cutting, metalworking, medical device manufacturing, automotive assembly, electronics, flexible packaging, gaskets, tapes, and much more. As a core converting process for flexible materials, rotary die cutting delivers both versatility and efficiency for manufacturing custom components at scale.

All it takes is flipping a switch and positioning a sizable sheet or roll of material beneath the rotary die system. This approach is perfect for engineering applications and custom die cut parts where it's critical that plastic, metal, or composite sheets are cut to exact dimensions, ensuring machinery and manufactured components fit and function precisely. With rotary die cutting, manufacturers can quickly produce parts for everything from automotive gaskets to electronics insulation, all while maintaining uniformity and minimizing material waste.

Rotary die cutting is also vital for producing bandages, custom adhesive sheets, gaskets, filters, tapes, and even specialized military equipment that demands strict adherence to dimensional specifications. With its unmatched repeatability, rotary die cutting enables manufacturers to achieve tight tolerances, minimize waste, and accelerate production cycles for a vast array of materials and products. Whether you need precision die cut adhesives, high-volume die cut labels, or custom foam cushioning, rotary die cutting offers a reliable, scalable solution.

How Does the Rotary Die Cutting Process Work?

To better understand the advantages and versatility of rotary die cutting, it's important to explore how the process works in detail. Are you wondering, What steps are involved in rotary die cutting and what makes this process unique among die cutting methods? Here’s a comprehensive overview that covers the fundamentals as well as advanced features:

At the heart of rotary die cutting is the rotary press, a machine that unrolls material and feeds it continuously between two synchronized cylindrical rollers. One roller acts as a hard, durable anvil, while the other is the rotary die—a precision-engraved cylinder equipped with sharp, heat-treated blades or cutting edges. This setup allows for efficient converting of both thin and thick materials, including laminates, films, and pressure-sensitive adhesives, into complex die cut shapes.

- Die Construction: Rotary dies may be solid engraved, machined from a single steel bar for maximum durability and tighter tolerances, or adjustable/flexible dies with replaceable blades, offering versatility for different material types, thicknesses, and patterns. Flexible dies are particularly useful for short runs and frequent design changes, while solid dies excel in long, high-volume production runs.

- Material Handling: Materials—such as plastics, metals, foams, paper, adhesives, films, textiles, rubber, or laminates—are fed into the rotary die cutting machine in sheet or roll form. Multiple material webs can be processed simultaneously, allowing for complex, multi-layered constructions needed in advanced applications such as electronics, automotive interior assemblies, and medical device components.

- Cutting Action: The die’s blades press the material against the anvil roller, shearing it cleanly and precisely at high speeds. This enables consistent, repeatable cuts with minimal burrs or defects, even on intricate designs and micro-perforations. The cutting action can be finely controlled to suit different material hardness and required cut depths.

- Secondary Operations: Rotary die cutting machines can also perform secondary processes in-line, such as perforating, scoring, creasing, slitting, laminating, embossing, and stacking. This streamlines production, reduces labor costs, improves throughput, and allows for the manufacturing of complex, value-added assemblies in a single pass.

Materials may exit the machine in different ways: they can be conveyed by a release liner (for adhesives and labels), rolled onto a new core, or sheeted into individual pads or stacks. The rotary die cutting machine can be configured for various cutting and finishing methods, each tailored for specific materials and end-use requirements:

- Metal-to-Metal Cutting: The die cuts completely through both the material and its release liner, producing clean, separate parts. This method is ideal for gaskets, seals, and other components that require separation from the web.

- Kiss Cutting: Also known as butt-cutting, this method cuts through the top layer (such as an adhesive, foam, or label stock) without piercing the backing liner, making it ideal for peel-and-stick applications, pressure-sensitive adhesives, and custom label production. For more on this specialized technique, see our guide to kiss cutting.

- Perforating and Scoring: Rotary die cutting can create tear lines, fold lines, or easy-open features for flexible packaging, envelopes, or custom cartons.

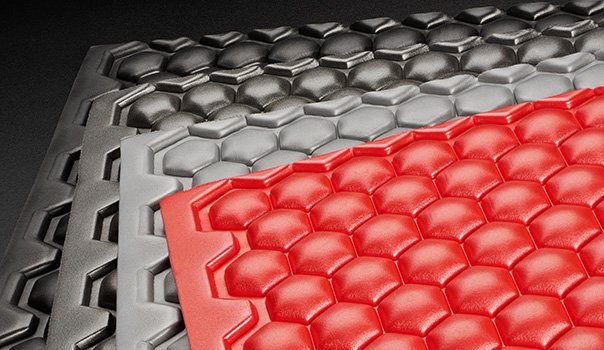

- Embossing and Debossing: Adding texture or raised/recessed features to packaging, gaskets, or decorative items.

Rotary die cutting’s versatility allows for simultaneous cutting, laminating, and assembly of multiple components. Advanced stacking processes can add complex elements such as island placement (precisely positioning small parts within a web), in-line packaging, and application of peel tabs, greatly increasing the range of functional products that can be manufactured efficiently. Rotary die cutting is also well-suited for integration with digital printing and automated inspection systems, supporting Industry 4.0 initiatives and real-time quality assurance.

Key Benefits of Rotary Die Cutting

Why do manufacturers, engineers, and product designers choose rotary die cutting over other fabrication and converting methods? Here are some of the core advantages that make rotary die cutting a preferred solution for high-precision, high-volume part manufacturing:

- Unmatched Precision and Consistency: Achieve tight tolerances and uniformity across high production volumes, reducing product variability and scrap while ensuring every component meets exacting standards. This is essential for applications in the medical, electronics, and automotive sectors where part consistency is critical.

- Speed and Efficiency: Rotary die cutting operates at high speeds (hundreds of feet per minute), making it ideal for large-scale production runs and projects with tight deadlines. Its continuous feed system maximizes throughput and minimizes downtime.

- Extreme Versatility: Compatible with a wide range of materials (including multi-layer laminates, composite structures, and specialty tapes), thicknesses, and complex part geometries. It supports both short runs for prototyping and long runs for mass production, all with minimal setup changes.

- Cost Savings: Automated production reduces labor costs, minimizes material scrap, and lowers per-part costs compared to manual, laser, or waterjet cutting techniques. In-line processes further reduce the need for secondary operations, saving time and resources.

- Integration with Secondary Processes: Lamination, slitting, perforating, embossing, stacking, and even in-line printing can be accomplished in one pass, reducing the need for multiple setups or machines and streamlining your supply chain.

- Customization and Rapid Tooling: Rotary dies can be manufactured to produce virtually any pattern, cutout, or configuration—supporting rapid prototyping, quick design changes, and full-scale production with minimal lead time. Modern die fabrication methods enable cost-effective custom solutions for unique part requirements.

- Low Maintenance and High Reliability: Rotary die cutting equipment is designed for continuous operation with minimal maintenance, resulting in optimal uptime and lower total cost of ownership, especially for demanding manufacturing environments.

Curious about how rotary die cutting compares to other cutting and converting methods? Explore the differences between flatbed die cutting, laser cutting, waterjet cutting, and digital cutting in our comprehensive die cutting process guide.

Common Applications of Rotary Die Cutting

Rotary die cutting is the preferred choice for producing precise, high-volume components in a variety of industries. Let’s explore some of the most common applications, use cases, and market sectors where rotary die cutting adds value:

Medical Devices and Wound Care Products

Rotary die cutting for adhesives and flexible materials solves numerous challenges in the medical industry. One of the most common products is medical adhesive tape, essential for wound closure, IV securement, surgical drapes, and wearable medical devices. Rotary die cut tapes and dressings are:

- Pressure-sensitive and breathable—providing secure adhesion while allowing the skin to breathe and heal comfortably. This is critical for patient comfort and medical efficacy.

- Available in custom shapes and sizes, tailored to patient needs, device requirements, or advanced wound care protocols.

- Manufactured from a variety of substrates, including waterproof films, hypoallergenic foams, medical-grade fabrics, silicone adhesives, hydrocolloid dressings, and more.

- Produced with high precision for consistent product performance, reducing the risk of skin irritation or improper wound coverage.

- Capable of high-speed inline production with sterilization-friendly materials, supporting regulatory compliance and just-in-time manufacturing for healthcare providers.

For OEMs and medical device manufacturers, rotary die cutting ensures every component meets stringent FDA and ISO standards. Looking for a reliable partner for your medical die cutting project?

Thermal Masking and Industrial Insulation

Industrial and commercial environments often face temperature regulation and electrical insulation challenges. Thermal masking tapes and insulation pads produced via rotary die cutting are applied to machinery, electronics, automotive components, and construction materials to:

- Provide effective insulation and thermal protection for sensitive or heat-prone equipment, including battery packs, printed circuit boards (PCBs), and industrial enclosures.

- Improve worker safety and comfort in cold climates by preventing condensation, heat loss, and equipment malfunction.

- Reduce energy costs and increase machinery lifespan by minimizing heat transfer and preventing component overheating.

- Enable precise, repeatable application through custom die cut shapes that fit complex surfaces or enclosures, reducing installation time and ensuring proper sealing.

- Support compliance with UL, RoHS, and other regulatory frameworks for electrical and fire safety.

Military and Defense Applications

Military equipment and protective gear require advanced materials with exceptional durability, environmental resistance, and performance reliability. Rotary die cut components are used to:

- Apply thermal insulation tape to boots, helmets, and uniforms, ensuring comfort and protection in extreme conditions such as deserts, arctic, or maritime environments.

- Coat weapons, vehicles, and communications equipment to prevent abrasions, scratches, or damage from environmental exposure, sand, dust, or corrosive agents.

- Enhance resistance to moisture, dust, and chemical agents with custom die cut gaskets, EMI/RFI shields, and weatherproof seals for electronics and communication gear.

- Meet stringent military specifications (such as MIL-SPEC standards) for reliability, uniformity, and rapid deployment, supporting mission-critical operations and supply chain security.

- Support quick prototyping and field-ready production of new equipment or retrofits for evolving defense needs.

Automotive, Electronics, and Industrial Manufacturing

Rotary die cutting is a go-to solution for producing gaskets, seals, shims, spacers, EMI/RFI shielding, pressure-sensitive adhesives, insulation pads, vibration dampening pads, and more. Typical use cases include:

- Automotive: Interior trim, dashboard overlays, badge adhesive, vibration dampening pads, protective films, acoustic insulation, heat shields, and custom labels for wiring harnesses.

- Electronics: Thermal interface materials, electrical insulation, keypad covers, screen protectors, flexible printed circuits, RFID tags, and precision die cut spacers for compact assemblies.

- Industrial: Custom packaging inserts, filtration membranes, foam cushioning, weatherstripping, specialty tapes, and industrial labels for asset traceability and logistics.

- Renewable Energy: Die cut films and insulators for solar panels, battery modules, and wind turbine components.

Want to know which rotary die cutting material or adhesive is best for your application? Compare material properties, cost, and performance. Need help specifying the right material for automotive or electronics die cutting? Start by browsing industry-specific use cases and customer reviews.

Labels, Stickers, and Packaging Solutions

Thanks to kiss cutting and high-speed precision, rotary die cutting is the industry standard for producing labels, stickers, decals, and pressure-sensitive adhesives used in retail, logistics, and product packaging. Die cut labels can be produced on rolls or sheets, in custom shapes and sizes, with in-line printing, lamination, and finishing options for inventory management, product branding, and tamper-evident security.

- Produce millions of individually die cut labels, nameplates, or barcodes for supply chain traceability and retail packaging.

- Integrate sequential numbering, variable data, or holographic overlays for product authentication.

- Leverage rotary die cutting for tamper-evident seals, anti-counterfeiting features, and promotional stickers.

Searching for “custom rotary die cut label manufacturers” or “die cut sticker suppliers near me”? Use our rotary die cutting supplier directory to compare capabilities and request samples.

Factors to Consider When Selecting a Rotary Die Cutting Company

Choosing the right partner for your rotary die cutting project is a critical step in ensuring product quality, cost efficiency, and timely delivery. Are you searching for “best rotary die cutting companies near me” or “custom die cutting services”? Here’s what to evaluate when reviewing potential suppliers and manufacturers:

- Industry Experience: Does the company have a proven track record in your specific sector (medical, automotive, electronics, packaging, industrial, defense, renewable energy, etc.)? Look for relevant case studies and customer testimonials.

- Material Capabilities: Can they process the types of materials and thicknesses your project requires—plastics, foams, films, metals, textiles, rubber, tapes, adhesives, or specialty composites? Do they offer sourcing and testing services for new material development?

- Equipment and Technology: Do they operate advanced rotary die cutting machines with tight tolerances, high-speed production, and in-line secondary operations? Are they equipped for digital printing, automated inspection, and robotic handling?

- Quality Assurance: Are their manufacturing facilities ISO-certified (ISO 9001, ISO 13485, IATF 16949)? Do they offer inspection, testing, and traceability for regulated industries such as medical, aerospace, or food packaging?

- Customization and Engineering Support: Will they assist with prototyping, design optimization, and rapid tooling for new product development? Do they provide CAD design, reverse engineering, and material selection support?

- Scalability: Are they equipped to handle both low-volume prototypes and high-volume production runs? Can they accommodate design changes or spikes in demand?

- Lead Times and Logistics: What are their typical turnaround times? Can they meet your delivery and inventory requirements with JIT (Just-In-Time) or Kanban systems? Do they offer warehousing or drop-shipping services?

- Customer Service: Do they provide clear communication, transparency, responsive support, and project management throughout the project lifecycle?

- Value-Added Services: Inquire about packaging, assembly, kitting, barcoding, or direct-to-line delivery options that can streamline your supply chain.

To ensure the best results, we recommend comparing several rotary die cutting companies using our rotary die cutting business directory. Each company profile highlights their expertise, material capabilities, certifications, and available services. Use our direct contact forms to request more information, ask for a quote, schedule a consultation, or discuss your project requirements in detail.

How to Request Quotes and Start Your Project

Ready to take the next step toward launching your custom die cutting project or securing a new supplier? Our platform makes it simple to connect with trusted rotary die cutting suppliers and manufacturers:

- Browse our directory and review company profiles, certifications, and material specialties in your target industry or location.

- Preview websites with our patented website previewer to evaluate each company’s experience, capabilities, and facility certifications.

- Use our streamlined RFQ (Request For Quote) form to submit your project details, drawings, and specifications to multiple companies at once, saving you valuable time during supplier sourcing.

- Compare quotes, lead times, material options, production capabilities, and value-added services to select the best rotary die cutting partner for your needs.

- Collaborate directly with engineering teams for prototyping, material selection, and design-for-manufacturability (DFM) support.

Have questions about rotary die cutting specifications, tolerances, or the best material for your application? Contact us or consult our resource center for technical support, in-depth buying guides, and expert advice on process optimization.

Frequently Asked Questions About Rotary Die Cutting

- What materials can be rotary die cut? Rotary die cutting is compatible with a wide range of materials, including plastics (PET, PVC, polycarbonate), metals (aluminum, copper, stainless steel foils), foams (urethane, silicone, neoprene), adhesives, paper, films (polyester, Kapton), textiles, rubber, and multi-layer laminates. The process is highly adaptable for custom applications and challenging substrates.

- What are the typical tolerances for rotary die cut parts? Tolerances depend on the die configuration and material, but rotary die cutting can often achieve tolerances as tight as ±0.005 inches (0.127mm), making it ideal for precision parts in electronics, medical devices, and automotive components.

- How does rotary die cutting compare to flatbed die cutting? Rotary die cutting is faster and better suited for high-volume production runs and continuous web materials, while flatbed die cutting may be preferable for thicker materials, low-volume runs, or applications requiring extremely intricate cuts and deeper embossing.

- Is rotary die cutting suitable for prototyping as well as production? Yes, rotary die cutting can be used for both rapid prototypes and full-scale production, thanks to rapid die manufacturing, flexible tooling options, and short setup times. Many suppliers offer quick-turn prototyping services to support new product development cycles.

- Can rotary die cutting integrate printing, laminating, or other finishing processes? Absolutely. Many rotary die cutting machines are equipped for in-line printing (flexographic or digital), lamination, embossing, slitting, and other value-added processes to create finished parts in a single pass, reducing your time to market.

- How do I choose the right rotary die cutting supplier? Evaluate suppliers based on experience, material capabilities, equipment, quality certifications, supply chain flexibility, and service. Our rotary die cutting directory is a great place to start your search and compare options.

- What types of industries benefit most from rotary die cutting? Key industries include medical devices, automotive, electronics, aerospace, packaging, renewable energy, defense, and industrial manufacturing. Rotary die cutting supports applications requiring high-volume, high-precision, and repeatable part production.

- What is the minimum order quantity for rotary die cut parts? Minimum order quantities (MOQs) vary by supplier, material, and part complexity. Many companies offer low MOQ options for prototyping or pilot production.

- Can rotary die cut parts be supplied with adhesive backing or custom packaging? Yes, most rotary die cutting suppliers can laminate pressure-sensitive adhesives, add release liners, and provide custom packaging, kitting, or labeling as needed.

Explore More About Rotary Die Cutting

For further information, technical resources, and advanced die cutting solutions, check out the following guides and directories:

- Plastic Die Cutting — Find solutions for PET, PVC, polycarbonate, and other plastics.

- Kiss Cutting — Learn about kiss cutting for labels, stickers, and pressure-sensitive adhesives.

- Die Cutting Machinery — Review the latest machine technologies and innovations.

- Rotary Die Cutting Suppliers — Connect with top-rated die cutting companies and request quotes.

Still have questions about rotary die cutting processes, materials, machinery, or suppliers? Contact us for expert advice, engineering support, or to discuss your custom die cutting project today. Our team can help you identify the best rotary die cutting solution based on your industry, application, and production goals.

Die Cutting

Die Cutting Foam Fab

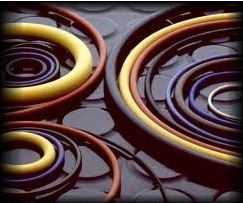

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services